Three-dimensional 3D printing, also known as additive manufacturing or digital fabrication technology, creates. Its physical objects through precise layer-by-layer deposition of material directly from a computer-aided design (CAD) model. A process of creating three-dimensional objects from a digital file by layering materials allows for the production of complex shapes with high precision and minimal waste.

What is 3D Printing?

Types of 3D Printing:

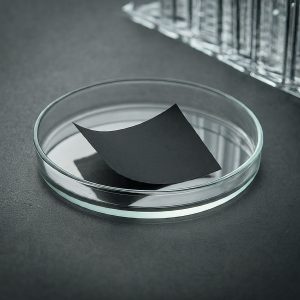

Stereolithography (SLA)

Invented by Chuck Hull in 1986, SLA is the first 3D printing technology and is often referred to as Vat Polymerization. It uses a laser to cure liquid resin into hardened plastic. Different types of resins like Standard, Castable, Transparent, and High-Temperature are available for various applications. An SLA printer uses mirrors, known as galvanometers, to direct a laser across the resin, curing each layer to form the object.

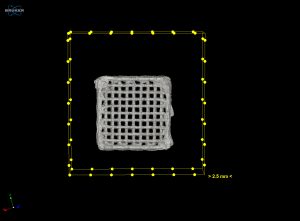

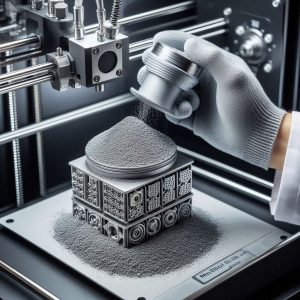

Selective Laser Sintering (SLS)

SLS utilizes Powder Bed Fusion, where a laser fuses powdered thermoplastic materials such as Nylon 6, Nylon 11, or Nylon 12. A thin layer of powder is spread, and the laser selectively sinters it, forming the object layer by layer. SLS is highly efficient for manufacturing functional parts, complex ducting, and low-volume production, although it comes with longer lead times and higher costs compared to other methods.

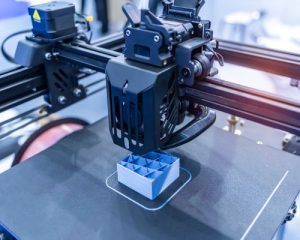

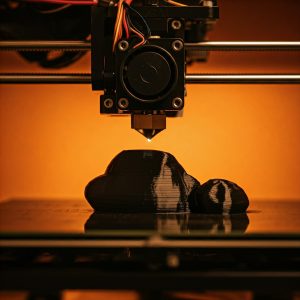

Fused Deposition Modelling (FDM)

Fused Deposition Modelling (FDM) Also known as Fused Filament Fabrication (FFF), FDM is the most common and cost-effective 3D printing technology. It works by extruding thermoplastic filament like PLA, ABS, or PET layer by layer to create objects. Common applications include electrical housings, form and fit testing, and jigs and fixtures. However, FDM parts can be brittle, making them less ideal for mechanical applications.

Digital Light Processing (DLP)

Digital Light Processing (DLP) Similar to SLA, DLP uses a projected light source to cure liquid resin. The main advantage of DLP is its speed, as it cures an entire layer at once. This makes it ideal for producing highly detailed items like toys, jewellery molds, and dental models.

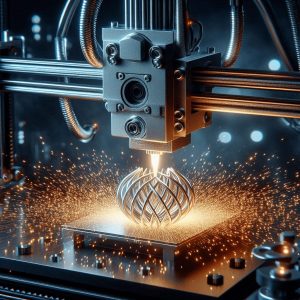

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM), uses a laser to fuse metal powder, making it perfect for producing high-resolution metal parts with complex geometries. This method is popular for low-volume production of industrial components, reducing the need for physical molds.

Multi Jet Fusion (MJF)

MJF is a cutting-edge process that uses a binding agent and heat to fuse powdered thermoplastics. Known for its high tensile strength and precise feature resolution, MJF is perfect for creating functional prototypes, end-use parts, and complex designs. Materials include Nylon PA11, Nylon PA12, and PP.

PolyJet

PolyJet jets layers of curable liquid photopolymer, making it capable of producing parts with multiple properties, including varying color and materials. This makes it ideal for prototyping elastomeric or over-moulded parts.

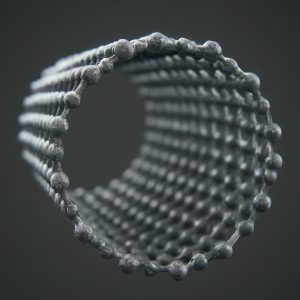

Electron Beam Melting (EBM)

EBM uses an electron beam to melt metal powder in a vacuum, making it ideal for high-temperature metal applications. It is widely used in industries requiring precision metal parts.

Selecting the right 3D printing process for your application requires an understanding of each process strengths and weaknesses and mapping those attributes to your product development needs.