Synthetic Ruby: The Gemstone Glow

Synthetic ruby is a pinkish red to blood-red gemstone, which belongs to the mineral corundum (aluminum oxide). Rubies are the second most popular gemstone after diamonds. It’s one of the most popular traditional jewelry gems and is highly durable. Other gem-quality corundum varieties are called sapphires. Rubies are part of the traditional cardinal gems, alongside amethyst, sapphire, emerald, and diamond. The color of a ruby is due to the presence of the element chromium. When heated to about 1800 degrees Fahrenheit, chromium-rich rubies can turn a more violet color. However, this treatment is not permanent, and the chromium will eventually bleed out of the stone, returning it to its original hue. This process, called “flux-heating,” is commonly used to improve the color of lower-quality rubies.

While natural rubies are certainly stunning, lab-created rubies offer many of the same benefits – and in some cases, even more.

Synthetic Ruby Powder: A Modern Alternative

Synthetic Ruby Powder Created in controlled laboratories, synthetic ruby powder replicates the natural formation process. The widely used Verneuil process involves melting powdered aluminum oxide with chromium oxide and allowing it to crystallize slowly. The resulting crystals share the same chemical composition and physical properties as natural rubies. Synthetic Ruby Powder: Designed to be nearly flawless, lab-grown ruby powder has fewer inclusions. Its excellent color and hardness closely match those of natural rubies. Synthetic Ruby Powder: Ethically sourced and sustainable, lab-created ruby powder offers an affordable option without the need for mining.

Synthetic Ruby Vs Natural Ruby

Natural Ruby Powder Formed over millions of years, natural ruby powder consists of genuine corundum with traces of chromium. It shares the same chemical composition as natural rubies. The color change depends on the amount of chromium present during formation. Synthetic Ruby Powder Created in controlled laboratories, synthetic ruby powder replicates the natural process. It forms within months, mirroring the chemical structure and properties of natural rubies. Natural Ruby Powder Often has inclusions and imperfections due to its geological origin. Synthetic Ruby Powder Virtually flawless, lacking the flaws found in natural rubies. It’s an ethical, sustainable, and budget-friendly choice.

Synthetic ruby powder benefits

Synthetic rubies are produced in controlled laboratory environments, allowing for consistent quality, purity, and properties. This uniformity is crucial in applications like industrial abrasives, optical components, and laser technologies, where precise and predictable material characteristics are essential. Natural rubies can vary significantly in color, clarity, and hardness due to natural impurities and inclusions. Synthetic rubies are generally more affordable than natural rubies. The controlled production process eliminates the variability and rarity associated with natural stones, resulting in lower costs. This makes synthetic rubies accessible for a wider range of applications, from consumer products like jewelry to industrial uses. The mining of natural rubies can lead to environmental degradation and sometimes involves unethical labor practices. Synthetic ruby production does not involve mining, making it a more sustainable and ethically responsible option. Consumers and companies increasingly seek environmentally friendly and ethically sourced materials, making synthetic rubies a preferable choice. Synthetic rubies can be engineered to meet specific requirements, such as size, shape, and color. This is particularly important in applications like watchmaking, where ruby bearings need to be precise and uniform. In contrast, natural rubies often require additional cutting and treatment to achieve the desired specifications, potentially introducing variability and additional costs. The supply of natural rubies can be limited and inconsistent, especially for high-quality stones. In contrast, synthetic rubies can be produced in large quantities on demand, ensuring a stable supply for industrial and commercial applications. This reliability is critical for industries that depend on a steady source of materials. In applications like lasers, synthetic rubies provide consistent optical properties, such as a specific wavelength output, which is crucial for the performance and precision of the devices. The controlled synthesis of rubies ensures that each crystal meets the exact specifications required for high-performance applications.

Synthetic ruby is better option for industry application

Synthetic ruby powder offers several advantages over natural rubies in various applications due to its controlled production process, cost-effectiveness, and consistent quality.

Consistency in Industrial Applications: Synthetic ruby powder is preferred in industrial applications requiring uniform particle size and hardness. This consistency is crucial for precise polishing and grinding, where natural rubies may vary in hardness and purity. For example, synthetic ruby powder is commonly used in the final polishing of high-precision lenses and optical components in scientific instruments.

Cost-Effectiveness in Jewelry: Synthetic rubies are a more affordable alternative to natural rubies in jewelry. They offer the same aesthetic appeal, including vibrant red color and high clarity, but at a fraction of the cost. Brands like Pandora and Swarovski use synthetic rubies in their jewelry collections, providing consumers with luxurious-looking pieces without the high price tag associated with natural rubies.

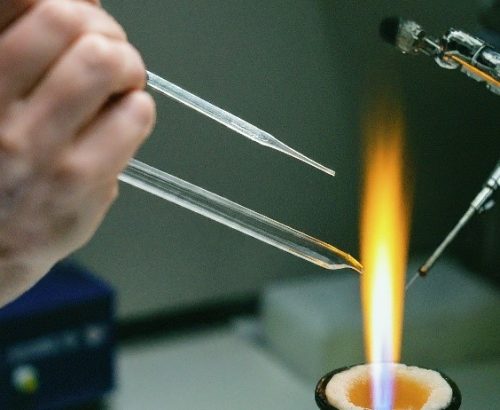

Controlled Properties in Scientific Instruments: In laser technology, the consistency and purity of synthetic rubies are essential. The first laser, a ruby laser, utilized a synthetic ruby crystal due to its precise properties, such as a specific wavelength output. The controlled synthesis of rubies ensures that each crystal meets the exact specifications required for high-performance laser applications, such as in medical treatments and research.

Ethical and Environmental Considerations: The production of synthetic ruby powder avoids the environmental and ethical issues associated with mining natural rubies. Mining can lead to habitat destruction and sometimes involves unethical labor practices. Synthetic rubies, produced in a controlled laboratory environment, offer a more sustainable and ethically sound alternative.

Specialized Applications in Watchmaking: Synthetic rubies are commonly used in watch bearings due to their hardness and low friction properties. Unlike natural rubies, synthetic rubies can be produced in specific shapes and sizes necessary for watchmaking, ensuring a perfect fit and optimal performance. Luxury watch brands, including Rolex and Patek Philippe, use synthetic ruby bearings to enhance the durability and accuracy of their timepieces.

Resent deployment and research on a synthetic ruby powder

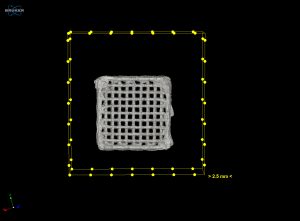

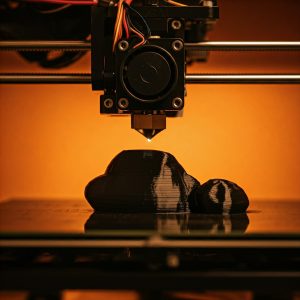

The research paper on ruby nanoparticles used in greenhouse farming demonstrates that photoconversion covers (PCC-R) based on ruby particles significantly enhance plant growth and yield. The study shows that PCC-R8 covers, in particular, improve water use efficiency and carbon dioxide assimilation in plants by efficiently converting green-blue radiation into red light, which is beneficial for photosynthesis. The synthesized ruby nanoparticles, with stable luminescent properties, were integrated into polymer matrices and effectively enhanced plant growth under laboratory conditions by optimizing light quality. Further investigations could explore the long-term durability of these photoconversion covers, their scalability for large-scale agricultural use, and potential cost reductions in production. Additionally, research into the effects of different nanoparticle sizes and compositions could optimize the efficiency of these covers for various plant species and environmental conditions. This study introduces a novel security printing ink that integrates Nano ruby with an eco-friendly chitosan-based formulation, offering advanced anti-counterfeiting features. The modified chitosan, known as CSNA, provides yellow fluorescence and stability, while the addition of ruby nanoparticles creates a composite ink (CSNAR) with distinct red and yellowish-orange emissions under specific UV light. This unique emission profile makes the ink difficult to replicate, enhancing document and product authentication through multi-level security features. This research presents a method for creating 3D-printed Cr³⁺-doped α-Al₂O₃ structures, also known as Ruby, using digital light processing and sol-gel chemistry. The aqueous solution with aluminum and chromium chloride and acrylic acid yields complex structures with a final resolution of 55.7 μm, surpassing the printer’s nominal resolution. Characterization shows these structures emit at 693 nm and possess impressive mechanical properties, indicating potential uses in thermal insulation, jewelry, and other applications. This study introduces a cost-effective stress sensor utilizing the luminescence response of ruby thin films. The sensor features a multilayer setup with a ruby film deposited by sputtering and a YBCO film deposited by A-MOCVD on a nickel tape substrate. Residual stress measurements, derived from shifts in ruby’s luminescent lines analyzed via Raman spectroscopy and calculated using the Stoney equation, demonstrate high accuracy. The method’s sensitivity, reliability, and affordability position ruby thin films as promising candidates for diverse stress-sensing applications.