HA coated Implants

Hydroxyapatite: The Key to Successful Implants

Hydroxyapatite (HA) is a mineral compound that has become a cornerstone in the world of medical implants. Its remarkable properties make it an invaluable material for enhancing the performance and longevity of implants.

What is Hydroxyapatite?

Hydroxyapatite is a naturally occurring mineral that is the primary component of human bones and teeth. Its structure and composition closely resemble those of the human skeletal system, making it highly biocompatible. This means it can coexist harmoniously with the body’s tissues without triggering an adverse immune response.

The Importance of HA coated Implants

- Osseointegration: The most significant advantage of HA is its ability to promote osseointegration. This is the process by which living bone grows directly into the implant, creating a strong and durable bond. HA’s porous structure acts as a scaffold for bone cells to attach and grow, leading to a more stable implant.

- Biocompatibility: As mentioned earlier, HA is highly biocompatible. This means it is well-tolerated by the body, reducing the risk of inflammation, rejection, and infection.

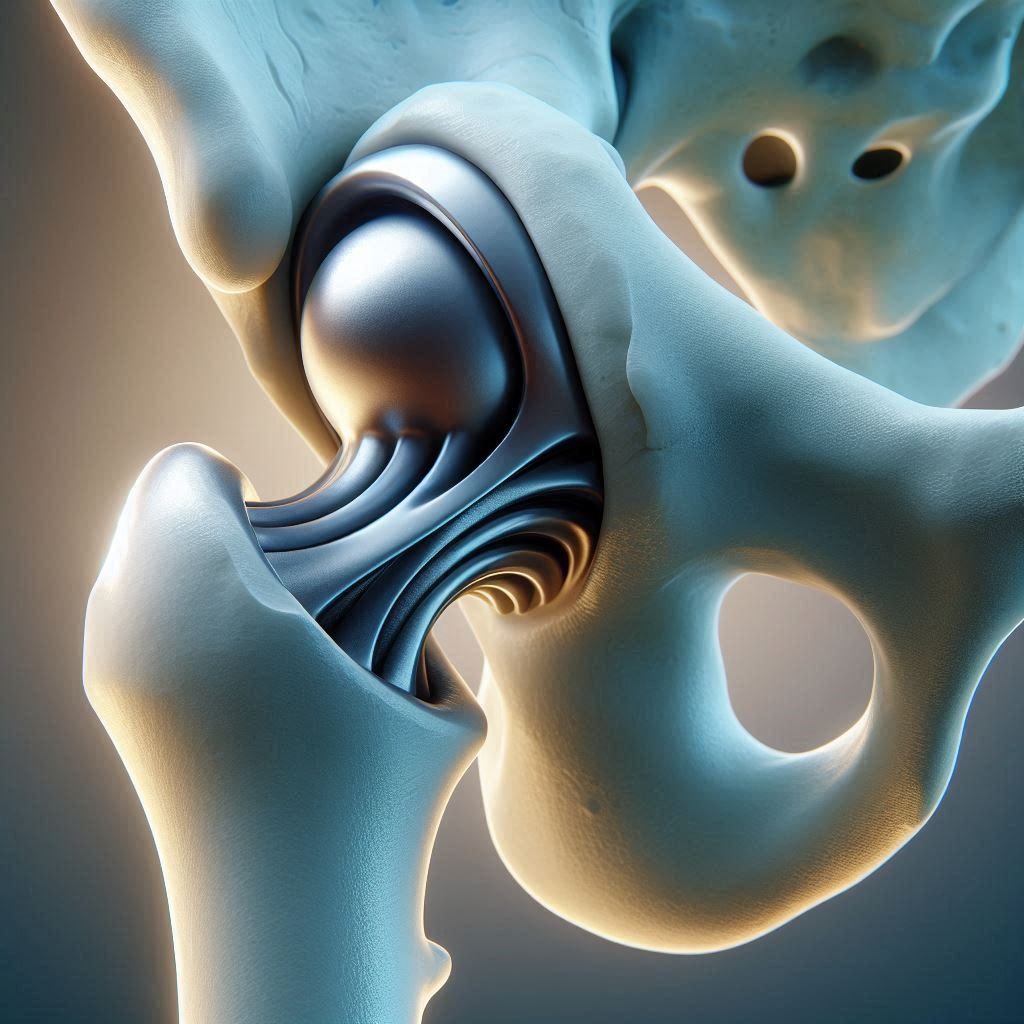

- Improved Wear Resistance: HA coatings can significantly enhance the wear resistance of implants, especially in high-stress areas like hip and knee replacements. This helps to prolong the implant’s lifespan and reduce the need for revision surgery.

- Pain Reduction: By promoting osseointegration and reducing wear, HA-coated implants can contribute to reduced pain and improved functionality for patients.

How is Hydroxyapatite Applied to Implants?

There are several methods to apply HA coatings to implants, including:

- Plasma Spraying: This involves melting HA powder and spraying it onto the implant surface, creating a porous coating.

- Electrochemical Deposition: This technique involves using an electric current to deposit HA onto the implant surface.

- Sol-Gel Process: This method involves creating a sol (a colloidal suspension) of HA particles, which is then applied to the implant and allowed to dry, forming a gel-like coating.

The Importance of Hydroxyapatite Coating in Light of the J&J Hip Implant Case

The Johnson & Johnson (J&J) hip implant case serves as a stark reminder of the importance of rigorous testing and safety measures in the medical device industry. The case centered around the company’s Acetabular Surface Replacement (ASR) hip implants, which suffered from a high rate of premature failure.

One of the factors that may have contributed to the failure of the ASR implants is the lack of a proper surface coating. Hydroxyapatite (HA) is a biocompatible material commonly used to coat implants. It promotes bone ingrowth and osseointegration, the process by which the implant bonds with the surrounding bone tissue.

Benefits of Hydroxyapatite Coating

Benefit | Description |

Enhanced Osseointegration | HA coating promotes bone ingrowth into the implant surface, creating a stronger and more stable fixation. This can significantly reduce the risk of implant loosening and failure. |

Improved Biocompatibility | HA coating minimizes the body’s foreign object response, leading to better long-term implant performance and reduced risk of infection. |

Reduced Wear and Tear | HA coating offers improved wear resistance, which can extend the lifespan of the implant and decrease the need for revision surgeries. |

The J&J Case and the Need for Improved Implants

The J&J ASR implants lacked a proper HA coating, which may have contributed to their early failure. The use of HA coating could have potentially improved the implant’s biocompatibility, osseointegration, and wear resistance, thereby preventing many of the problems experienced by patients.

Conclusion

The J&J hip implant case highlights the critical role of material science and proper implant design in ensuring patient safety and long-term success of joint replacement surgeries. Hydroxyapatite coating offers a valuable solution for improving implant performance and biocompatibility. As the medical device industry continues to evolve, prioritizing rigorous testing and utilizing advanced materials like HA coating will be essential for developing safe and effective implants that can improve patients’ lives.

Implant Allergies and the Importance of Coatings

Allergies to implants, while not as common as other types of allergies, can occur. These reactions are often due to the body’s immune system recognizing the implant material as a foreign object. This can lead to a variety of issues, including:

- Inflammation: The body’s natural response to foreign bodies is inflammation. When an implant isn’t coated or is coated with a material the body rejects, it can trigger chronic inflammation.

- Rejection: In severe cases, the body may reject the implant entirely. This can lead to implant failure and the need for removal.

- Allergic Reactions: Some individuals may develop specific allergies to implant materials. This can result in symptoms like itching, redness, swelling, or even more severe reactions.

HA Coating Characterization: Ensuring Quality and Performance

Hydroxyapatite (HA) coatings have become indispensable in the realm of implant technology due to their exceptional biocompatibility and osteoconductive properties. To guarantee the optimal performance of these coatings, rigorous characterization is essential. Let us delve into various techniques employed to assess the quality and properties of HA coatings.

Understanding the Importance of Characterization

Thorough characterization is crucial for several reasons:

- Quality Control: Ensuring the coating meets specified standards and is free from defects.

- Performance Prediction: Relating coating properties to implant performance in vivo.

- Process Optimization: Improving coating deposition techniques for better results.

- Troubleshooting: Identifying issues in the coating process or material.

Key Properties of HA Coatings

Several key properties are typically evaluated:

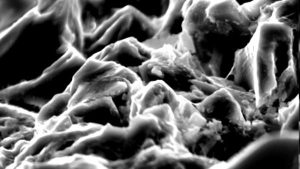

- Microstructure: The internal structure of the coating, including grain size, porosity, and phase composition.

- Thickness: The thickness of the coating, which influences its mechanical properties and bioactivity.

- Porosity: The presence of pores, which can affect bone ingrowth and implant fixation.

- Bonding Strength: The adhesion of the coating to the substrate, crucial for long-term implant stability.

- Crystallinity: The degree of crystallinity of the HA phase, affecting its mechanical properties and bioactivity.

- Chemical Composition: The stoichiometry of the HA coating, ensuring it matches the desired calcium-to-phosphorus ratio.

Characterization Techniques

A combination of techniques is often employed for a comprehensive evaluation:

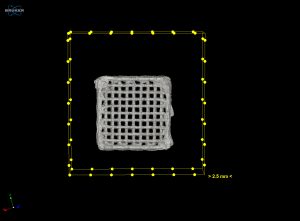

- Scanning Electron Microscopy (SEM): Provides high-resolution images of the coating surface morphology, microstructure, and thickness.

- Energy-Dispersive X-ray Spectroscopy (EDS): Determines the elemental composition of the coating, verifying the HA stoichiometry.

- X-ray Diffraction (XRD): Identifies the crystalline phases present in the coating and assesses crystallinity.

- Atomic Force Microscopy (AFM): Offers high-resolution imaging of surface topography and roughness.

- Fourier Transform Infrared Spectroscopy (FTIR): Identifies functional groups present in the coating, confirming the presence of HA.

- Nanoindentation: Measures the mechanical properties of the coating, such as hardness and elastic modulus.

- In Vitro Bioactivity Tests: Evaluates the ability of the coating to induce bone-like apatite formation in simulated body fluid.

HA-Coated Implants: A Clinical and Economic Perspective

Hydroxyapatite (HA) coatings have significantly advanced the field of implantology. While the benefits in terms of biocompatibility and osseointegration are well-established, it’s crucial to evaluate their impact from a clinical and economic standpoint.

Clinical Outcomes of HA-Coated Implants

Numerous clinical studies have demonstrated the advantages of HA-coated implants.

- Improved Osseointegration: HA coatings have consistently shown to enhance bone-implant integration, leading to increased implant stability and reduced risk of failure. This is particularly evident in challenging bone conditions.

- Reduced Revision Rates: Several studies have reported lower revision rates for HA-coated implants compared to their non-coated counterparts. This translates to fewer surgical procedures and improved patient outcomes.

- Enhanced Patient Satisfaction: Patients who received HA-coated implants often report higher satisfaction levels due to reduced pain, faster recovery, and improved functional outcomes.

Economic Impact of HA-Coated Implants

The economic implications of HA-coated implants are multifaceted.

- Initial Costs: HA-coated implants typically have a higher upfront cost compared to non-coated implants due to the additional processing steps involved.

- Long-Term Savings: Despite the higher initial cost, HA-coated implants can lead to significant long-term savings. Reduced revision rates, shorter hospital stays, and improved patient outcomes can offset the initial investment.

- Cost-Effectiveness: A comprehensive cost-benefit analysis is required to determine the overall economic impact of HA-coated implants. Factors such as implant lifespan, patient quality of life, and societal costs should be considered.

HA Coatings in Specific Applications

HA Coatings in Orthopedic Implants

Orthopedic implants, such as those used in hip, knee, and spine surgeries, have significantly benefited from HA coatings.

- Hip Implants: HA-coated hip implants have shown improved osseointegration, leading to enhanced implant stability and reduced risk of loosening. The coating promotes bone growth into the implant, creating a stronger bond between the artificial and natural components.

- Knee Implants: Similar to hip implants, HA coatings on knee replacements contribute to better implant fixation and reduced wear. The coating can also help in pain reduction and improved patient mobility.

- Spine Implants: In spinal surgery, HA-coated implants can accelerate fusion between vertebrae, leading to faster recovery and reduced pain. The coating’s osteoconductive properties support bone growth around the implant, aiding in spinal stability.

HA Coatings in Dental Implants

Dental implants have revolutionized tooth replacement, and HA coatings play a vital role in their success.

- Osseointegration: HA-coated dental implants exhibit superior osseointegration, ensuring a strong and stable foundation for artificial teeth. The coating promotes bone growth around the implant, preventing implant failure.

- Peri-implantitis Prevention: HA coatings can help prevent peri-implantitis, a condition characterized by inflammation around the implant. The coating’s biocompatibility reduces the risk of bacterial colonization and subsequent inflammation.

HA Coatings in Other Medical Fields

Beyond orthopedic and dental applications, HA coatings have found utility in various medical fields.

- Maxillofacial Surgery: In reconstructive surgeries, HA-coated implants can be used to replace bone defects. The coating promotes bone regeneration and integration, leading to improved aesthetic and functional outcomes.

- Cardiovascular Implants: While still in the experimental stages, HA coatings are being explored for cardiovascular implants to enhance biocompatibility and reduce thrombogenicity.

- Bone Regeneration: HA coatings are used in bone grafts and scaffolds to promote bone healing and regeneration. The coating provides a suitable environment for bone cells to grow and proliferate.

Emerging Trends in HA Coated Implants

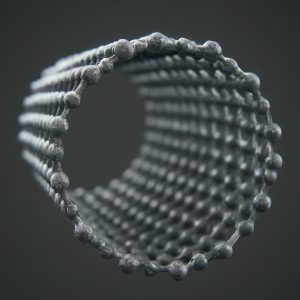

- Nanostructured HA Coatings: By manipulating HA at the nanoscale, researchers are developing coatings with enhanced properties. These nanostructured coatings can promote faster bone growth, improve implant stability, and enhance the overall performance of implants.

- Combination Coatings: Combining HA with other biomaterials, such as bioactive ceramics or polymers, can create synergistic effects. These composite coatings can offer tailored properties for specific implant applications, such as improved wear resistance, antibacterial properties, or drug delivery capabilities.

- Functionalized HA Coatings: Incorporating bioactive molecules, growth factors, or drugs into HA coatings can provide additional benefits. For example, growth factor-loaded HA coatings can stimulate bone regeneration, while antimicrobial coatings can prevent implant-associated infections.

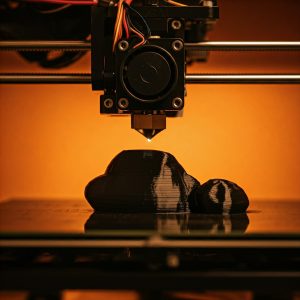

- 3D Printed HA Coatings: Advances in 3D printing technology allow for the creation of complex and customized HA coatings. This approach enables the design of implants with tailored pore structures and mechanical properties, leading to improved osseointegration and implant performance.

Potential Applications and Benefits

- Regenerative Medicine: HA coatings are playing a crucial role in tissue engineering and regenerative medicine. By providing a suitable scaffold for cell growth, HA-coated implants can be used to repair damaged tissues and organs.

- Dental Implants: HA-coated dental implants offer excellent biocompatibility and osseointegration, leading to improved implant stability and reduced risk of failure.

- Orthopedic Implants: HA coatings are widely used in orthopedic implants to enhance bone-implant integration and reduce the incidence of implant loosening.

- Maxillofacial Implants: HA coatings are increasingly used in maxillofacial surgery to improve the integration of implants with bone tissue, leading to better aesthetic and functional outcomes.

The future of hydroxyapatite coatings holds immense promise for improving the lives of patients with orthopedic, dental, and other medical conditions. As technology continues to evolve, we can expect to see even more innovative and effective HA-based implants emerge in the years to come.