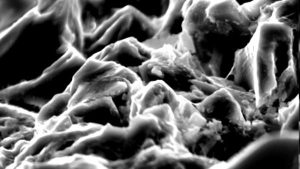

Cobalt powder is a fine, grey metallic material known for its exceptional properties and wide range of applications. Its unique characteristics make it indispensable across numerous industries, driving innovation in fields like energy, aerospace, and medical technologies.

Cobalt Powder: From Batteries to Superalloys

Physical and Chemical Properties

Cobalt powder boasts several remarkable physical and chemical traits:

High Magnetic Permeability: Cobalt’s strong magnetic properties make it ideal for creating permanent magnets and magnetic recording media.

Excellent Corrosion Resistance: Cobalt is highly resistant to environmental corrosion, ensuring longevity and reliability in harsh conditions.

High Melting Point: With a melting point of 1495°C (2723°F), cobalt is well-suited for high-temperature applications, including superalloys and biomedical implants.

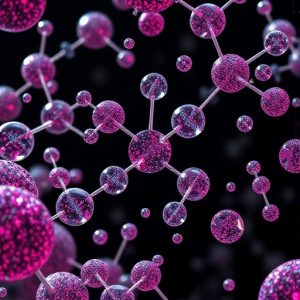

Catalytic Activity: Cobalt compounds act as effective catalysts in chemical processes, such as the Fischer-Tropsch synthesis for converting syngas into liquid fuels.

Applications of Cobalt Powder

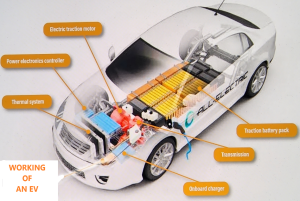

Battery Technology:

Cobalt is a key component in lithium-ion batteries, which power devices like smartphones, laptops, electric vehicles (EVs), and grid storage systems. Its presence enhances battery energy density and lifespan, ensuring efficient and long-lasting performance.

Superalloys:

Cobalt contributes to the development of superalloys that offer exceptional strength, heat resistance, and durability. These materials are essential for critical applications in jet engines and gas turbines.

Magnetic Materials:

Cobalt’s magnetic properties are crucial for producing permanent magnets used in motors, generators, and MRI machines. These applications highlight its importance in both industrial and medical fields.

Cobalt powder adds vibrant blue hues to ceramics and glass, making it a favorite in artistic and decorative applications. Additionally, it is used to create corrosion-resistant coatings, extending the lifespan of various materials.

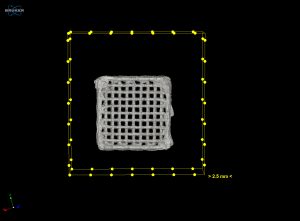

Metallurgical Processes:

In metallurgy, cobalt plays a vital role in sintering cutting blades, producing ceramic glazes, and electroplating. These processes enhance material performance and durability.

Chemical Catalysis:

Cobalt compounds are indispensable in chemical industries. They enhance lubrication performance, act as antioxidants to prevent material degradation, and serve as antifouling agents in industrial systems.

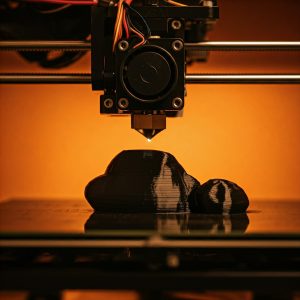

Future Innovations

The demand for cobalt powder continues to grow as industries innovate and adopt new technologies. Its role in advancing energy storage solutions, developing more efficient superalloys, and driving sustainable chemical processes ensures its relevance in the future. With ongoing research into alternative cobalt sources and recycling methods, the material is poised to remain a cornerstone of technological progress.

Cobalt powder’s versatility and reliability make it a key player in shaping the future of multiple industries. Its unique properties and wide-ranging applications ensure that it will continue to be a vital resource in the years to come.