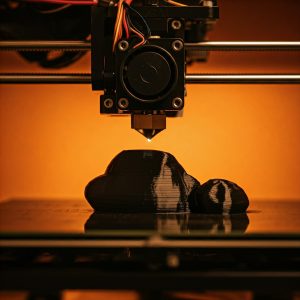

Cobalt-Chromium-Molybdenum (CoCrMo) alloy powder is the ultimate choice for making by 3D printing implants related to hips, knees, elbows, shoulders, ankles, fingers, bone plates, screws, staples & heart valves. The alloy has superior mechanical strength, outstanding wear resistance, and exceptional biocompatibility.

Cobalt-Chromium-Molybdenum (CoCrMo) alloy powder is the ultimate choice for making by 3D printing implants related to hips, knees, elbows, shoulders, ankles, fingers, bone plates, screws, staples & heart valves. The alloy has superior mechanical strength, outstanding wear resistance, and exceptional biocompatibility.

Cobalt-Chromium-Molybdenum (CoCrMo) Alloy Powder for Biomedical Applications

Why Choose CoCrMo Alloy Powder?

Unmatched Mechanical Strength: CoCrMo alloys provide excellent durability & strength, making them ideal for load-bearing implants such as hip and knee replacements. Their high toughness ensures longevity, even under extreme conditions.

Exceptional Corrosion Resistance: Designed to withstand biological environments, CoCrMo alloys offer superior corrosion resistance, ensuring implants remain stable and functional for extended periods.

Biocompatibility & Osseointegration: Safety is paramount in medical applications, and CoCrMo alloys excel in biocompatibility. They integrate seamlessly with human bone and tissue, reducing the risk of adverse reactions.

Non-Magnetic & Imaging Friendly: Unlike other metal alloys, CoCrMo is non-magnetic, making it suitable for patients requiring frequent MRI scans without interference.

Key Applications of CoCrMo Alloy

Prosthetic Replacements: Hips, knees, elbows, shoulders, ankles, and fingers.

Prosthetic Replacements: Hips, knees, elbows, shoulders, ankles, and fingers.

Orthopedic Implants: Bone plates, screws, staples, and rods.

Dental Solutions: Crowns, bridges, and dental implants.

Cardiovascular Devices: Heart valves and stents.

How CoCrMo Compares to Other Alloys

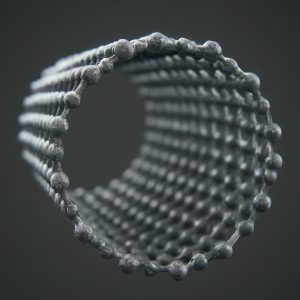

CoCr alloys exhibit a modulus nearly 20 times higher than bone, whereas titanium alloys (modulus 5–8 times that of femur bone) offer better strain and deformation control. Despite this, CoCr alloys remain preferred for their reduced deformation and exceptional wear resistance.

Industry Compliance & Standards

Regulated under ASTM F75, CoCrMo alloys meet strict mechanical property requirements, ensuring safety and reliability in medical applications.

Its superior strength, biocompatibility, and corrosion resistance make it the gold standard in medical device manufacturing.