Exploring High-Performance Ceramics: Applications, Materials, and Innovations in Advance Ceramics

Advance ceramics, often referred to as engineered ceramics, represent a fascinating realm of materials with exceptional properties. Unlike their traditional counterparts, advanced ceramics are purposefully designed for specialized applications that demand superior mechanical, thermal, and chemical characteristics. Let’s delve into the world of advanced ceramics, focusing on calcium aluminate (CaAl₂O₄) and Another material stands out for in advance materials its exceptional stability at high temperatures is a magnesium aluminate, commonly known as spinel its applications, synthesis methods, and recent innovations.

Thermal Properties: While not as refractory as alumina, calcium aluminate can withstand moderate temperatures. Its rapid-setting ability is crucial in specific applications.

Mechanical Properties: Although possessing decent compressive strength, calcium aluminate falls short of the hardness and wear resistance exhibited by alumina.

Chemical Behaviour: It remains relatively stable in alkaline environments but reacts with acids.

Synthesis of Calcium Aluminate:

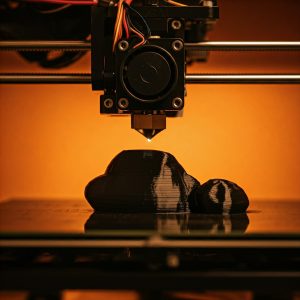

Solid-State Reaction: A mixture of calcium oxide and alumina undergoes controlled heating to form calcium aluminate.

Solution-Based Methods: Fine-grained calcium aluminate powders can be synthesized using sol-gel or precipitation techniques.

Applications in Comparison:

Quick-Hardening Refractories: Calcium aluminate cements find their niche in constructing refractory concretes for furnaces and kiln linings. The rapid set allows efficient repairs and maintenance.

Oil and Gas Industry: Well cementing sealing underground formations requires materials with high-temperature resistance and quick-setting properties. Calcium aluminate cements fit the bill.

Recent Innovations:

Environmental Remediation: CaAl₂O₄ spinel nanoparticles, synthesized via the sol-gel method, exhibit remarkable hydrogen storage capacity. These nanoparticles hold promise for addressing organic dye discharge in environmental clean-up.

Earth’s Mantle Insights: Evolutionary crystal structure prediction algorithms reveal that CaAl₂O₄ remains stable in Earth’s lower mantle. Its CaFe₂O₄-type structure under high pressures sheds light on mantle formation.

Future Directions:

Construction Materials: Self-healing calcium aluminate cements with embedded repair mechanisms could enhance durability and reduce maintenance costs.

Fire Protection: Lightweight, high-temperature-resistant calcium aluminate-based foams may revolutionize thermal insulation and fire protection in buildings.

Oil and Gas Exploration: Investigating calcium aluminate cements for extreme well conditions high temperatures and pressures holds immense potential.

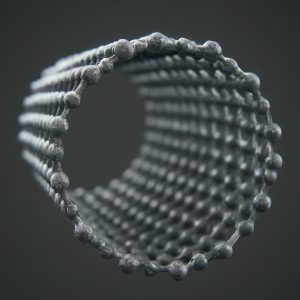

When it comes to advanced ceramics, one material stands out for its exceptional stability at high temperatures: magnesium aluminate, commonly known as spinel. Explore the fascinating properties, applications, and recent innovations related to this remarkable ceramic.

Spinel’s Thermal Resilience:

Thermal Shock Resistance: Spinel exhibits excellent resistance to thermal shock, making it ideal for severe service conditions.

High-Temperature Stability: Even under extreme heat, spinel remains stable, retaining its mechanical properties.

Mechanical Strength and Wear Resistance:

Strength: While not as hard as alumina, spinel still boasts good strength.

Wear Resistance: It holds up well against wear, especially considering its ability to maintain mechanical properties at high temperatures.

Chemical Inertness:

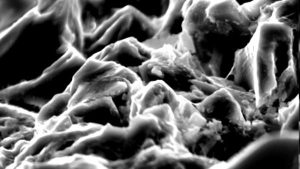

Properties: High purity, fine particle size, good sintering properties.

Advantages: Versatility in starting material leads to a host of ceramic products.

Best suited for: Advanced ceramics, abrasives, coatings.

Synthesis Methods:

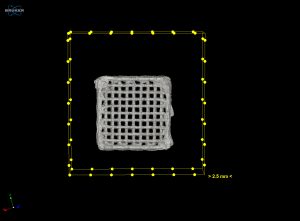

Solid-State Reaction: A high-temperature calcination of a mixture of magnesium oxide and alumina yields magnesium aluminate.

Sol-Gel Method: Fine-grained spinel powders can be synthesized using sol-gel techniques.

Applications:

Refractory Materials: Spinel finds its place in refractory bricks and crucibles for high-temperature applications in steelmaking, glassmaking, and ceramics. Its resistance to thermal shock and corrosion makes it indispensable.

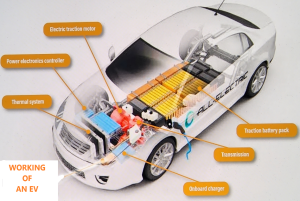

Electronic Packaging: Spinel ceramics serve as substrates for electronic components, thanks to their heat conductivity and electrical insulation.

Recent Innovations:

Hydrogen Storage: MgAl₂O₄ spinel nanoparticles synthesized via sol-gel processes exhibit remarkable hydrogen storage capacity. These nanoparticles hold promise for hydrogen storage technologies.

Supercritical Synthesis: A novel process produces high-purity fine-crystal MgAl₂O₄ spinel by treating a mixture of finely divided MgO and aluminum hydroxide under supercritical conditions.

Future Directions:

Transparent Spinel: Research explores transparent spinel for laser applications, optical fibres, and infrared windows.

Wear-Resistant Coatings: Spinel coatings enhance wear resistance in aggressive environments, such as aerospace and automotive components.

Energy Conversion: Investigating spinel-based materials for solid-oxide fuel cells and electrolyzers.

Conclusion:

Development in the field of advanced ceramics is a continuous process, where the researchers continuously strive to develop new materials and upgrade existing stock to keep pace with the ever-growing demand of modern technology. Advanced ceramics thus play a significant role in pushing advances in different technological sectors, improving efficiency, and reliability for many systems and devices.

Now, as we go deeper into advanced ceramics, the innovative scope is endless. With the help of materials like Calcium Aluminate and Magnesium Aluminate we are at the frontier of a new era in technologies that rivals a few. The ways that they can mold our future: from breakthroughs in energy storage to modernizing healthcare, are limitless. Further research, development, and interdisciplinary collaboration on these very special substances are requisite toward unlocking their full potential. Advanced ceramics hold promise for sustainable, efficient, and new solutions to the complex problems arising in today’s environment.

All India Metal Corporation: Delivering Advance Metal solutions you can rely on. Consistent quality, unmatched performance.