Graphene Tyres - Revolutionizing Automobile Driving

Graphene oxide is transforming the automotive industry by revolutionizing tyre performance. Graphene oxide addition to rubber is an emerging & exciting alternative to traditional fillers like carbon black in tyre manufacturing.

Graphene Oxide blends used in tyre blend recipes, offers numerous benefits like:

Increased fuel efficiency

enhanced road performance

lower operating costs.

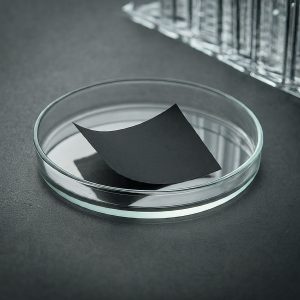

Understanding Graphene Oxide

Graphene oxide is a well-known functionalized derivative of graphene arranged on a two-dimensional honeycomb lattice with oxygen-containing groups like epoxides, hydroxyl, and carboxyl. The functional groups are introduced chemically by oxidation. This makes graphene oxide a material with vastly divergent & distinct characteristics.

Unique Properties of Graphene Oxide:

High Surface Area: Graphene oxide retains the high surface area of graphene, allowing for extended interaction with other materials. This property is crucial for various applications.

Hydrophilicity: Unlike hydrophobic graphene, Graphene oxide is hydrophilic and disperses easily in water. This makes it ideal for water-based systems and composites.

Enhanced Reactivity: The oxygen groups in Graphene oxide enhance its reactivity, enabling further modifications and functionalization.

Conductivity: Although less conductive than pristine graphene, Graphene oxide can still carry electricity. Reduction processes can modulate its conductivity.

Mechanical Strength: Graphene oxide maintains much of the mechanical strength of graphene, contributing to the development of durable materials.

Fuel Efficiency on Wheels

Graphene oxide significantly improves fuel efficiency in automobiles by reducing rolling resistance. This reduction minimizes energy losses due to tyre deformation, allowing vehicles to travel longer distances as compared to conventional rubber tyres on a single tank of fuel. Studies show that rolling resistance can be reduced by up to 19.4%, resulting in real-world fuel savings.

Impact on Tyre Durability

The use of Graphene oxide in tyre technology has a profound impact on durability:

Internal Friction Reduction: Enhanced interaction between fillers and rubber molecules reduces internal friction and viscous losses in rubber composites.

Improved Dispersion: Incorporating modified Graphene oxide into natural rubber composites improves dispersion within the rubber matrix. This leads to superior tensile strength, elongation at break, heat resistance, and abrasion resistance—critical for eco-friendly tyre applications.

Surface Enhancements: Graphene oxide addition to tyres along with components like hexagonal boron nitride and white carbon black, significantly improves abrasion resistance, heat dissipation, and overall performance. This extends tyre service life and ultimately increases tyre life & reduce running costs.

Beyond Efficiency: Enhanced Performance

Improved Grip: Enhanced tyre performance ensures better handling and control, especially in wet or slippery conditions.

Increased Durability: Superior wear resistance extends tyre lifespan, reducing replacement expenses.

Reduced Heat Buildup: Improved heat dissipation lowers the risk of tyre blow-outs, which is crucial for large & small commercial vehicles & passenger cars.

Puncture Resistance: Graphene oxide provides greater resistance to punctures and damage from road debris.

Advantages Of Graphene Oxide Tyre Over Traditional Tyre

Improved Dispersion Ability: Graphene oxide based tyres exhibit better dispersion of graphene oxide within the rubber matrix. This leads to more consistent material properties and enhanced overall performance.

Strong Interfacial Interactions: The modified graphene oxide forms strong bonds with the polymer matrix, resulting in improved structural integrity and durability.

Reduced Rolling Resistance: Graphene oxide reduces hysteresis during tyre rolling, which translates to lower energy loss and improved fuel efficiency.

Enhanced Safety: Graphene oxide tyre offer reliable performance, contributing to safer transportation.

Hybrid Elastomeric Composites: By incorporating graphene oxide, tyre technology has achieved a balance between rolling resistance and durability.

Pavement Performance: Graphene oxide integration in rubber asphalt enhances road quality, especially in high-traffic areas with varying temperatures.

Environmental Benefits Of Graphene Oxide Tyres

The utilization of graphene oxide in tyre manufacturing offers significant environmental advantages.

Enhanced Fuel Efficiency: Graphene oxide incorporating into tyre treads, manufacturers achieve improved fuel efficiency. The reduction in rolling resistance allows vehicles to cover more distance on a single tank of fuel. Studies indicate that rolling resistance can be reduced by up to 31%, resulting in real-world fuel savings.

Reduced Environmental Footprint: The adoption of Graphene oxide tyres contributes to a lower environmental footprint during production. Graphene oxide unique properties enhance mechanical strength, such as increased tensile strength and modulus. At the same time, it effectively reduces rolling resistance. This dual benefit translates to fewer resources consumed during tyre manufacturing.

Prolonged Tyre Lifespan: The strong interface between Graphene oxide and the rubber matrix enhances wear resistance. Graphene oxide tyres have a longer lifespan, reducing the need for frequent replacements. Fewer discarded tyres mean less waste and a positive impact on the environment.

Quantifiable Evidence: Measurements of tensile strength, elongation at break, rolling resistance reduction percentage, and wear resistance improvement provide tangible evidence of graphene oxide’s positive environmental impact. These parameters demonstrate the sustainability achieved by integrating graphene oxide into tyre technology.

The Future Of Tyres

Exceptional properties of graphene oxide are a game-changer for the automotive tyre industry & represent the future of driving, by making transportation greener and more efficient.

Enhanced Durability and Performance: Graphene promises to enhance tyre wear resistance, making them last longer and perform better. By minimizing rolling resistance, graphene tyres aim for improved fuel efficiency and reduced carbon emissions.

Sustainable Production: The eco-conscious crowd is all ears. Scientists are investigating green methods to incorporate graphene into tyres. Recycling is a sustainable twist on tyre production.

Longevity Unleashed: These tyres are designed to outlast traditional ones, promising extended mileage and durability. Whether you’re cruising city streets or embarking on a cross-country adventure, graphene tyres have your back.

Improved Dispersion Ability: Graphene oxide-based tyre exhibits better dispersion of graphene oxide within the rubber matrix. This leads to more consistent material properties and enhanced overall performance.

Sustainability and Recycling: The future of eco-friendly tyre lies in sustainable graphene-based materials. These advanced tyres not only promise better performance but also emphasize environmental responsibility. By recycling graphene-infused rubbers, we can close the loop and make a positive impact on the planet.

Manufacturing Companies Leading the Way

The interest in graphene oxide underscores its potential to transform tyre technology. As companies invest in research and development, we can expect better-performing, more sustainable tyres in the near future.

Apollo Tyres (India): explores graphene potential in advanced tyre compounds.

Grip Enhancement: Better road grip ensures safer driving, especially in high-performance scenarios.

Extended Lifespan: Graphene helps create longer-lasting tyre.

Michelin (France): Michelin the French tyre giant, has delved into graphene capabilities. Their research focuses on incorporating graphene into tyre compounds to achieve two critical goals

Longevity: Graphene reinforcement enhances tyre lifespan, allowing drivers to go the extra mile.

Grip: Improved traction ensures safer handling, especially during challenging road conditions.

Goodyear: synonymous with innovation, has explored graphene’s impact on tyre treads

Strength and Resilience: By integrating graphene, Goodyear aims to create treads that withstand wear and tear, providing durability and reliability.

Heat Dissipation and Wear Reduction: Graphene’s unique properties contribute to better heat management and reduced tread wear.

Continental (Germany): German tyre company, has experimented with graphene to enhance tyre rubber.

Traction Boost: Integrating graphene improves tyre traction, ensuring better road grip.

Extended Lifespan: The goal is to produce tyre that last longer, reducing the need for frequent replacements.

Pirelli (Italy): Italian tyre manufacturer, sees graphene as a key ingredient for high-performance tyre.

Safety First: Pirelli’s research aims to develop tyre with improved safety and handling characteristics.

Efficiency Optimization: By optimizing graphene’s properties, they create more efficient tyre designs.

Bridgestone (Japan): Japanese tyre giant, is researching graphene incorporation.

Wear Resistance: Graphene-infused rubber enhances tyre durability, reducing wear over time.

Fuel Efficiency: Lower rolling resistance contributes to improved fuel efficiency.

Nokian Tyres (Finland): Nokian, known for winter tyre, explores graphene benefits of winter traction

Icy and Snowy Surfaces: Graphene enhances traction, improving safety in harsh winter conditions.

Performance in Extremes: Nokian aims for reliable tyre performance when it matters most.

Vittoria (Bicycle Tyre): Vittoria, specializing in bicycle tyre, introduces graphene-infused option of a cycling efficiency

G+ Isotech Compound for bicycle tyres : The graphene-infused compounds offer durability, puncture resistance, and efficient rolling for cycling enthusiasts.

Graphene oxide is paving the way for a new era in automotive technology, promising a more sustainable and cost-effective future for drivers everywhere.

Explore our graphene oxide (AIGO) and revolutionize your tyres.

It can be easily used as an additive in your tyre manufacturing process & enhance tyre performance, durability, efficiency & provide value-addition.