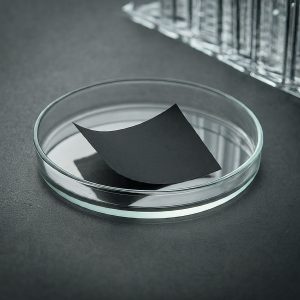

The Graphene Oxide INK is known as carbon-based organic ink or Graphene-based ink. Graphene oxide is highly dispersible in water and polar organic solvent due to its polar nature and the presence of oxygen-containing functional groups. Graphene oxide exhibits good colloidal stability in water, preventing aggregation and maintaining a uniform dispersion.

Graphene oxide ink has many advantages over other metal-based conductive inks, especially those which rely on silver and copper, which makes it a highly sought-after product with many interesting potential applications. In addition to being exceptionally strong, transparent and non-toxic, it is also a more environmentally-friendly alternative to silver-based inks. Silver, is expensive & is difficult to recycle, which means that every single-use electronic product must be disposed off carefully. Graphene, on the other hand is eco-friendlier & can be used for printed electronics.

Graphene Oxide INK

What is graphene oxide commonly used for?

Graphene oxide commonly used for in various sector including Graphene/polymer composite materials, Batteries, Biomedical, Solar cells, Supercapacitors, Support for metallic catalysts, Low permeability materials, Biosensors, Multifunctional materials, Graphene research and Rubber & Tyre Industry.

What Is Graphene Oxide Ink?

Like other conductive inks, graphene ink can be used to create printed materials which conduct heat and electricity. Modern uses of conductive ink include printing train tickets, plane boarding passes and RFID (radio-frequency identification) tags, but it has a vast range of useful applications. It has also made its way into mainstream manufacturing, and is now commonly used for the production of smart packaging.

Types of Graphene Oxide Ink

Aqueous Ink: These are water-based formulations, making them environmentally friendly and easy to handle.

Solvent-Based Ink: These inks use organic solvents, offering better adhesion and faster drying times.

Conductive Ink: Specifically designed to maintain high electrical conductivity, making them ideal for printed electronics and other applications requiring efficient charge transfer.

Productivity of Graphene Oxide Ink

Graphene oxide ink is produced using a simple and fast method, making it easier to prepare compared to existing methods. The resulting ink remains stable in water suspension for at least a month without the need for surfactants or additional solvents. These inks offer a stable dispersion of graphene oxide, high viscosity, good printability, and long shelf life. Freeze-dried and annealed patterns provide low electrical resistivity and high surface area. The ink exhibits excellent electrochemical properties, making it suitable for applications in sensors and energy devices.

Applications of Graphene Oxide Ink

The widespread use of graphene oxide ink could open up many different possibilities. Here we will discuss some of the sectors where it could be particularly useful.

Smart Packaging: Manufacturers are always looking for new ways to meet consumer demands and transform the retail experience. Printed electronics could be used to allow packaging to communicate with potential customers, whether by telling them that packaged food has perished or that the temperature of their medication has fallen below the optimum level.

Wearables: Electronic wearables could soon become commonplace thanks to exciting new printing technology. Cotton can now be modified with graphene-based inks, which could be used to produce conductive clothing. Electronic textiles would be especially beneficial for those in the healthcare, fitness and lifestyle industries, and could also revolutionize the way we design military wear.

Wearables: Electronic wearables could soon become commonplace thanks to exciting new printing technology. Cotton can now be modified with graphene-based inks, which could be used to produce conductive clothing. Electronic textiles would be especially beneficial for those in the healthcare, fitness and lifestyle industries, and could also revolutionize the way we design military wear.

It is within the field of sportswear that electronic textiles are making perhaps the largest strides. Smart shoes are currently in production, and could be used by athletes to measure exactly where they’re exerting the most pressure during exercise.

Touch Screens: Graphene impressive strength and flexibility means that it could soon be used in the production of (Organic Light-Emitting Diodes) OLED touch screens and panels. As phone and tablet manufacturers compete to impress their customers with new and improved features, the race towards creating a flexible OLED screen is an active one. The conductivity of graphene-based inks also makes them an ideal component in the production of new touch screen technology.

Disposable Sensors: Scientists succeeded in printing disposable biosensors with a conventional roll-to-roll method. Biosensors are typically very expensive to produce, meaning that many researchers continue to examine cells under a microscope rather than investing in biosensors. Making biosensors with graphene rather than gold or platinum could significantly reduce the production costs, and make their use more widespread in pharmaceuticals.

Disposable Sensors: Scientists succeeded in printing disposable biosensors with a conventional roll-to-roll method. Biosensors are typically very expensive to produce, meaning that many researchers continue to examine cells under a microscope rather than investing in biosensors. Making biosensors with graphene rather than gold or platinum could significantly reduce the production costs, and make their use more widespread in pharmaceuticals.

Graphene-Based Inks can be recycled easily, which means that they could be used to create disposable, single use materials, including biosensors. This could have a range of applications within the pharmaceutical industry, such as in the production of blood glucose biosensors used all over the world by people with diabetes.

Graphene-Based Inks can be recycled easily, which means that they could be used to create disposable, single use materials, including biosensors. This could have a range of applications within the pharmaceutical industry, such as in the production of blood glucose biosensors used all over the world by people with diabetes.

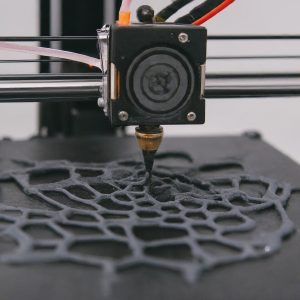

3D Printing : 3D printing has gone from strength to strength in recent years, with a huge amount of research focusing on the benefits of using graphene-based inks. Graphene inks are easy to incorporate into various plastics like PET or 3D printing filaments. This makes it easy to make 3D printed objects with novel properties.

3D Printing : 3D printing has gone from strength to strength in recent years, with a huge amount of research focusing on the benefits of using graphene-based inks. Graphene inks are easy to incorporate into various plastics like PET or 3D printing filaments. This makes it easy to make 3D printed objects with novel properties.