Shaping the Future: The Transformative Potential of 3D Printing

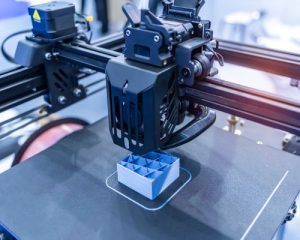

Future of 3D Printing : What was once a futuristic concept is now a cornerstone of innovation across a multitude of industries. 3D printing, a technology that has captured the imagination of visionaries and pioneers, is rapidly evolving and poised to reshape the world as we know it. Let’s explore the most promising developments that are defining the future of this transformative technology.

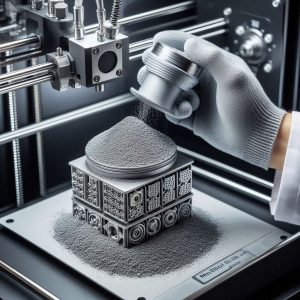

Material Revolution: Beyond the Boundaries of Plastics

The current frontier of 3D printing is expanding well beyond the confines of traditional plastics. Researchers and innovators are now developing the capability to print with a diverse array of materials, including metals, ceramics, and even living tissues. This material revolution is unlocking unprecedented possibilities, as the ability to print functional materials with specific properties, such as conductivity, flexibility, and biocompatibility, comes within reach.

Speed and Scale: Accelerating Production and Expanding Horizons

Advancements in printing technology are leading to significant improvements in production times, making 3D printing a more viable option for mass manufacturing. Gone are the days of slow, laborious printing processes; the future promises faster turnaround, enabling 3D printing to be a more competitive and practical solution. Moreover, the ability to print larger objects, including entire buildings and structures, is becoming a reality, expanding the scope and scale of what can be achieved through this transformative technology.

Industry Disruption: Reshaping Healthcare, Aerospace, and Beyond

The impact of 3D printing is being felt across a multitude of industries, each experiencing its own unique transformation. In the healthcare sector, 3D printing is revolutionizing the landscape, with applications ranging from personalized prosthetics to organ transplantation and customized medical devices. The aerospace and automotive industries are also embracing 3D printing, leveraging its potential to create lightweight and complex components, improving efficiency and performance. Furthermore, the decentralized manufacturing enabled by 3D printing holds the promise of optimizing supply chains, reducing reliance on global networks and enhancing overall resilience.

3D Printing & Healthcare

3D printing, once a futuristic concept, is rapidly transforming the healthcare industry. From prosthetics to organ transplantation, the possibilities are endless. Let’s explore how this groundbreaking technology is set to revolutionize medicine.

Personalized Medicine: A Tailor-Made Approach

- Custom Implants and Prosthetics: 3D printing allows for the creation of highly customized implants and prosthetics that perfectly match a patient’s anatomy, improving both function and comfort.

- Drug Delivery Systems: Personalized drug delivery systems can be designed and manufactured using 3D printing, ensuring optimal drug release and patient compliance.

Revolutionizing Surgery and Treatment

- Surgical Planning and Simulation: 3D printed models of patient anatomy can help surgeons plan complex procedures with greater precision, reducing risks and improving outcomes.

- Organ and Tissue Engineering: While still in its early stages, 3D bioprinting holds the promise of creating functional organs and tissues for transplantation.

- Point-of-Care Manufacturing: On-demand production of medical devices and tools at the point of care can streamline procedures and reduce costs.

Democratizing Healthcare

- Accessibility and Affordability: 3D printing has the potential to reduce the cost of medical devices and increase accessibility to healthcare, especially in remote areas.

- Rapid Response to Emergencies: In crisis situations, 3D printing can be used to quickly produce essential medical supplies, such as ventilators and protective equipment.

3D Printing and Aerospace

The future of 3D printing in the aerospace industry holds exciting possibilities. Let’s explore some key trends and innovations:

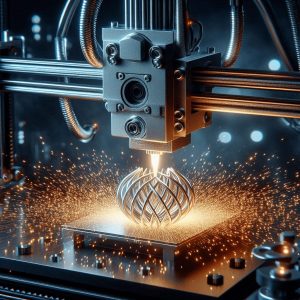

- Complex Part Production: In recent years, aerospace companies have embraced 3D printing for creating intricate, customized parts. From rocket engines to aircraft components, additive manufacturing (AM) enables the production of complex geometries that were previously challenging to manufacture. This trend is likely to continue, with companies like Boeing, Lockheed Martin, and SpaceX leading the way.

- Digital Thread Integration: The aerospace sector recognizes the importance of predictive modeling and the digital thread. By connecting various stages of the manufacturing process digitally, companies can achieve better quality control and optimize their value stream. Boeing, for instance, has already integrated 40% of its value stream into the digital thread, guiding AM builds with simulations for first-time success.

- On-Site 3D Printing: Expect companies to develop on-site 3D printing operations. This move would reduce supply chain costs, shipping delays, and storage expenses for parts. Additionally, on-site printing capabilities allow real-time design adjustments, rapid prototyping, and customized part implementation.

- Advancements in Materials: Researchers are continually exploring new materials for aerospace applications. High-performance polymers, advanced metals, and even graphene-based composites are being tested. These materials enhance strength, durability, and thermal resistance, making them ideal for aerospace components.

- Sustainability Focus: As environmental concerns grow, aerospace companies are looking for sustainable solutions. 3D printing reduces material waste, energy consumption, and transportation emissions. Expect further innovations in eco-friendly materials and processes.

The potential of 3d printing in the defense sector is vast and exciting. Here’s a glimpse into the future:

Distributed Manufacturing: With advancements in 3d printing technology, it’s conceivable that military units could produce essential equipment and spare parts right in the field, reducing reliance on long supply chains.

Material Innovation: New materials with specific properties, such as enhanced strength, durability, and heat resistance, will expand the range of applications for 3d printed components.

AI Integration: Combining 3d printing with artificial intelligence could optimise designs, predict component failures and automate production processes.

Ethical considerations: As 3d printing becomes more accessible, there will be growing concerns about potential misuse of the technology, especially in the production of weapons.

The automotive industry is going through a transformative shift, and 3d printing is at the heart of revolution. The innovative technology is reshaping how cars are designed, manufactured, and repaired.

Speeding up the design process:

3d printing has revolutionized automotive sector by speeding up the prototyping process. What used to be time-consuming and expensive is now much faster. Engineers can iterate on designs swiftly, testing concepts without relying on physical molds or tools. This agility translates to quicker development cycles and faster time-to-market for new vehicles.

Creating complex components:

3D printing is great at making intricate and complex parts that are hard to create using regular methods. Car manufacturers use it for lightweight, high-performance components like engine parts and interiors. Plus, 3D printing lets them make custom parts for specific car models or individual preferences.

Enhancing vehicle performance:

3D printing contributes to better vehicle performance by optimizing component design and material selection. For example, engineers can create lightweight parts that reduce vehicle weight, leading to improved fuel efficiency and handling. Additionally, the ability to produce complex internal structures enhances strength and durability.

Supply chain optimization:

3D printing has the potential to transform automotive supply chains. By making spare parts as needed, manufacturers cut inventory costs and ensure better part availability. In emergencies like recalls or unexpected shortages, 3D printing allows rapid responses, minimizing downtime and inconvenience for customers.

The convergence of artificial intelligence and 3D printing is ushering in new era of manufacturing, where innovation and efficiency are redefined. These two powerful technologies are complementing each other in ways that were once unimaginable. It opens up exciting possibilities across various industries like:

Personalized Back support with AI and 3D Printing:

Ukrainian tech start up Lemki Robotix developed a personalized back support called “Back Care.” It combines AI and 3D printing to address back and neck pain caused by poor posture or uncomfortable seating.

Users capture images of their body posture using a mobile app. AI processes these images to create anatomical data, which informs the design of the customized back support.

AI Designed 3D printed houses:

Litehaus, a pioneering company, leverages AI to revolutionize the design and construction of 3D printing homes. Their first project, located in Portugal, marks the world’s first AI designed, 3D printed house. This integration of AI in both interior and exterior design represents a groundbreaking development.

Generative Design

AI algorithms can autonomously generate multiple design alternatives based on input parameters like materials, manufacturing methods desired properties.

As 3D printing becomes more accessible and widespread, the need to address sustainability and ethical considerations becomes increasingly paramount. The development of biodegradable and recycled materials is crucial for making 3D printing a more eco-friendly and sustainable solution. Simultaneously, the rise of 3D printing raises important questions around intellectual property rights, the potential for counterfeiting, and the ethical implications of technologies that could be misused, such as the 3D printing of weapons. Navigating these challenges will be essential as the future of 3D printing unfolds.

The future of 3D printing is brimming with excitement and potential. From revolutionizing healthcare to reshaping entire industries, the transformative power of this technology is becoming increasingly evident. As the boundaries of materials, speed, and scale continue to be pushed, we can expect to witness groundbreaking applications that will redefine the way we live, work, and solve global challenges. The future is here, and it is being shaped by the remarkable advancements in 3D printing.