For several years, stainless steel has been extremely popular in different industries due to its durability, corrosion resistance, and beauty. However, conventional ways of manufacturing have prevented it from obtaining complex geometries and design freedom. The technique of additive manufacturing (AM), or rather 3D printing is a game changer in this regard. This is a technology that is changing how we are implementing stainless steel by opening up new possibilities.

Unlocking the Potential of Stainless Steel through an Additive Manufacturing Method

Understanding Additive Manufacturing

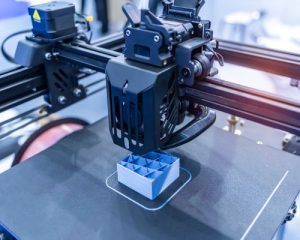

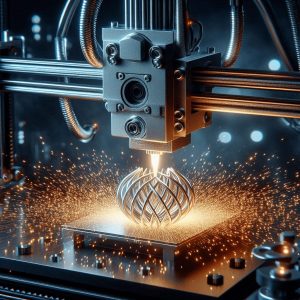

Additive manufacturing builds objects layer by layer making it possible for intricate designs and complex shapes that would otherwise be impossible or too expensive with traditional methods. Here are some advantages of this particular technology:

Additive manufacturing builds objects layer by layer making it possible for intricate designs and complex shapes that would otherwise be impossible or too expensive with traditional methods. Here are some advantages of this particular technology:

Design Freedom – Create complex geometries and internal channels without limitations.

Material Efficiency – Using material only where it’s needed reduces waste.

Consolidation of Parts – Merge many parts into one for better performance and cost effectiveness.

Rapid Prototyping – Accelerate product development cycle.

Stainless Steel and Additive Manufacturing: A Perfect Match

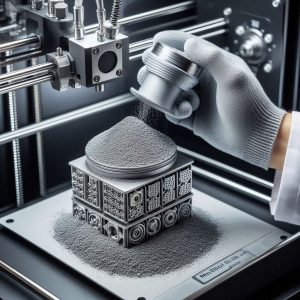

AM is a great technique to employ for stainless steel because of its characteristics. It has strength, biocompatibility and corrosion resistance which makes it applicable in many cases. Here are some benefits of using AM for stainless steel:

Improved Performance: For instance, you can produce parts with enhanced heat resistance or high strength-to-weight ratio.

Functional Integration: You can incorporate features like cooling channels or sensors into your part.

Customization: This means that you can design components to meet specific requirements.

Cost-Effective Production: This will reduce material wastage as well as production time and thus lowering the costs.

Applications across Industries

Stainless steel’s versatility makes it indispensable in numerous industries. Here are some common applications:

Food and Beverage Industry: Kitchen equipment, food processing machinery, and storage tanks.

Construction: Architectural cladding, roofing, structural components, and handrails.

Automotive Industry: Exhaust systems, body panels, and trim components.

Medical Industry: Surgical instruments, implants, and medical equipment.

Chemical Processing: Tanks, pipes, and valves for handling corrosive substances.

Marine Industry: Hulls, decks, and equipment due to its corrosion resistance to saltwater.

Understanding Steel Grades

Stainless steel is categorized based on its microstructure and chromium content. The most common types are:

Austenitic Stainless Steel: Containing chromium and nickel, this type is non-magnetic, highly ductile, and offers excellent corrosion resistance.

Grade 304: The most common, versatile grade, used in kitchen appliances, automotive parts, and construction.

Grade 316: Offers superior corrosion resistance than 304, ideal for marine environments and chemical processing.

Grade 304L: A low-carbon version of 304, used in welding applications to prevent corrosion.

Ferritic Stainless Steel: Containing chromium but no nickel, these steels are magnetic and have good corrosion resistance.

Grade 430: The most common, used in automotive parts, kitchen equipment, and architectural applications.

Grade 410: Offers higher strength than 430, suitable for cutlery and industrial components.

Martensitic Stainless Steel: Contains carbon and chromium, is magnetic, and can be hardened.

Grade 420: Used in cutlery, surgical instruments, and pump shafts due to its hardness and edge retention.

Choosing the Right Grade

Selecting the appropriate stainless steel grade depends on the specific requirements of an application. Consider the following factors:

Corrosion Resistance: Different grades offer varying levels of resistance to different corrosive environments.

Strength and Hardness: Some grades are stronger and harder than others, suitable for high-stress applications.

Machinability: Certain grades are easier to machine than others, impacting production costs.

Weldability: Some grades weld better than others, affecting fabrication processes.

Cost: The price of stainless steel varies depending on the grade and alloying elements.

Why Grade 316L Shines in AM

Excellent Corrosion Resistance: 316L’s high chromium and molybdenum content provides superior resistance to a wide range of corrosive environments, making it ideal for applications in the marine, chemical, and medical industries.

Good Mechanical Properties: This grade offers a balance of strength, ductility, and toughness, essential for components subjected to various loads and stresses.

Biocompatibility: 316L is widely used in medical implants due to its excellent biocompatibility, making it a prime choice for AM produced medical devices.

Buildability: 316L exhibits good buildability in most AM processes, resulting in parts with consistent mechanical properties and minimal defects.

Applications of 316L in AM

Medical Implants: From orthopedic implants to dental components, 316L is used to create complex and customized implants with improved patient outcomes.

Aerospace: AM enables the production of lightweight and high-performance components for aircraft and spacecraft using 316L.

Oil and Gas: The material’s corrosion resistance makes it suitable for producing AM parts for harsh environments in the oil and gas industry.

Automotive: 316L is employed to manufacture complex and lightweight components for high-end vehicles.