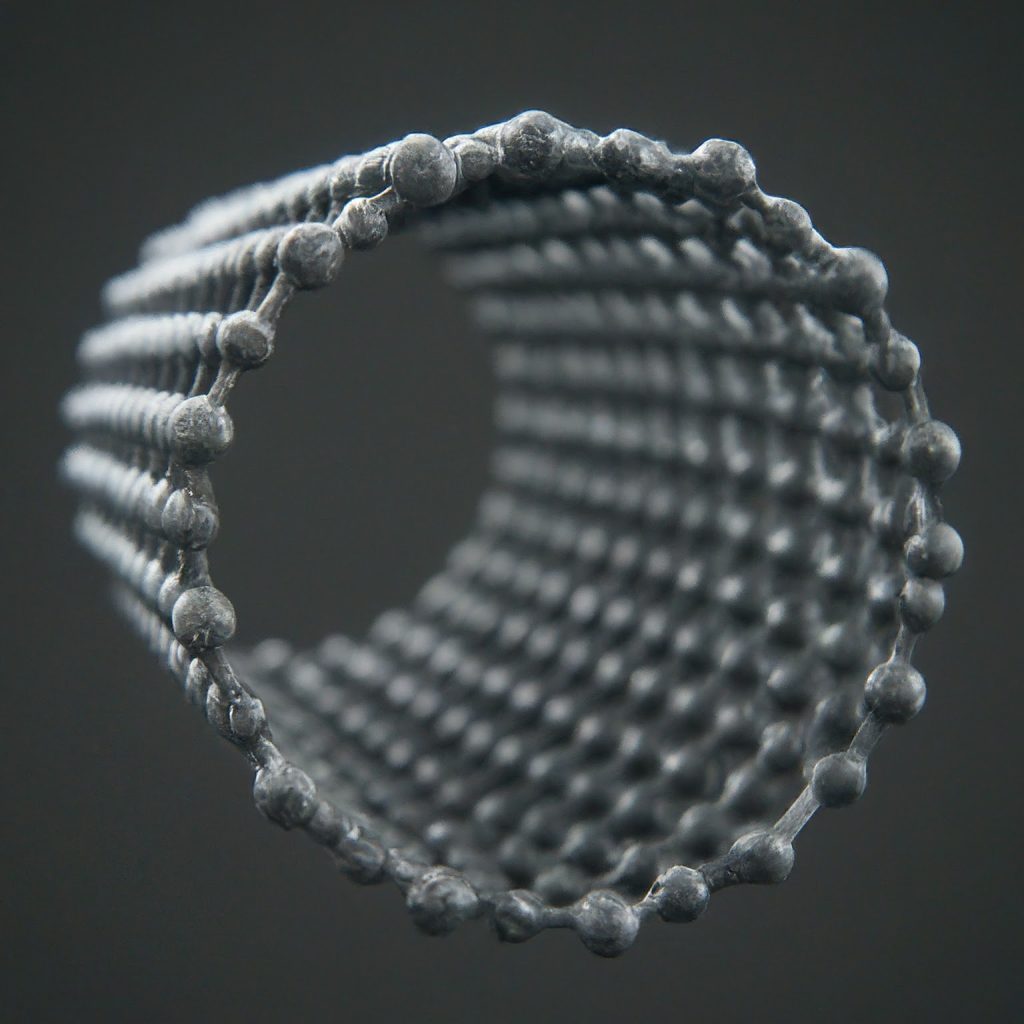

Multi-walled carbon nanotubes (MWCNTs) are widely applied in coatings to enhance mechanical

strength, resist corrosion, and interact effectively in biological contexts. Incorporating MWCNTs with

materials such as titania improves adhesion, corrosion resistance, and modifies surface structure,

making them ideal for applications involving osteoblast adhesion. Additionally, MWCNTs enhance

permittivity parameters when integrated into gelatin nanocomposites, studied via FTIR and SEM

analyses for their interactions with polymers. In corrosion protection coatings, combining MWCNTs

with Zinc has proven effective against corrosive agents, with varying ratios influencing performance.

In electronic devices, MWCNTs coatings provide inherent conductivity, ideal for creating antistatic

films that dissipate electrostatic charges and safeguard sensitive electronics. For marine

applications, MWCNTs coatings enhance corrosion resistance and reduce biofouling on ships and

offshore structures exposed to harsh saltwater environments.

MWCNTs coatings with high thermal conductivity are utilized on heat sinks to enhance heat

dissipation from electronic components, thereby improving operational efficiency and reducing

temperatures. In aerospace, MWCNTs coatings on aircraft components manage heat during flight,

contributing to overall efficiency and performance.

In sensor technology, MWCNTs are investigated for sensitive and flexible sensors, with promising applications in environmental monitoring, healthcare diagnostics, and wearable electronics.

Ongoing research addresses environmental and health concerns related to MWCNTs, emphasizing the importance of following safety protocols during handling and usage. The effectiveness of MWCNTs coatings relies on optimizing dispersion and surface functionalization to achieve desired properties systematically. As MWCNTs research continues to evolve, we can expect even more innovative applications to emerge. The future of MWCNTs coatings is bright, promising a world of stronger, more durable, and multi-functional surfaces across various industries.

Unleash the power of AIMCOM’s Multi-Wall Carbon Nanotubes (MWCNTs)—tiny cylinders with

colossal potential! Join us at All India Metal Corporation and shape the future today!