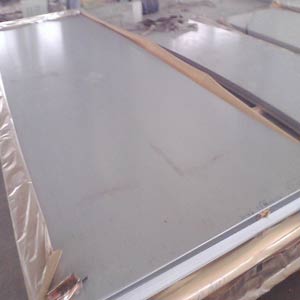

Aluminized Steel Coil

Type 1

Heat resistance

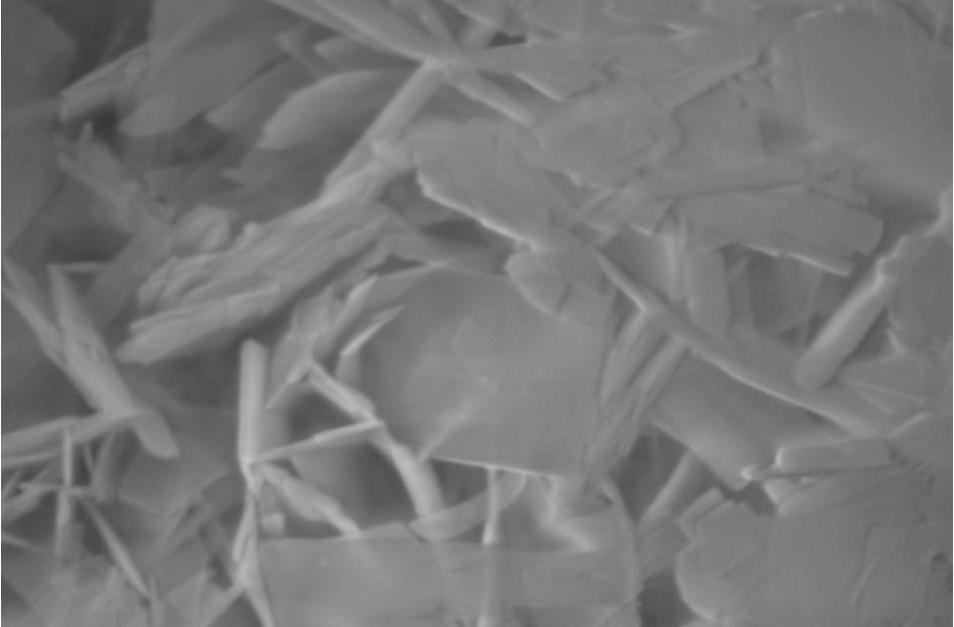

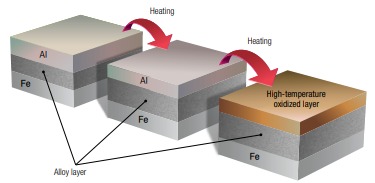

Aluminized steel for the most part shows neither change in appearance nor discoloration even if heated for long times at temperatures of 4000C. However, above 4000C, the surface transforms to a layer of Al-Fe alloy which usually creates discoloration, however, heat as well as corrosion-resistant properties remain intact up to about 6000C.

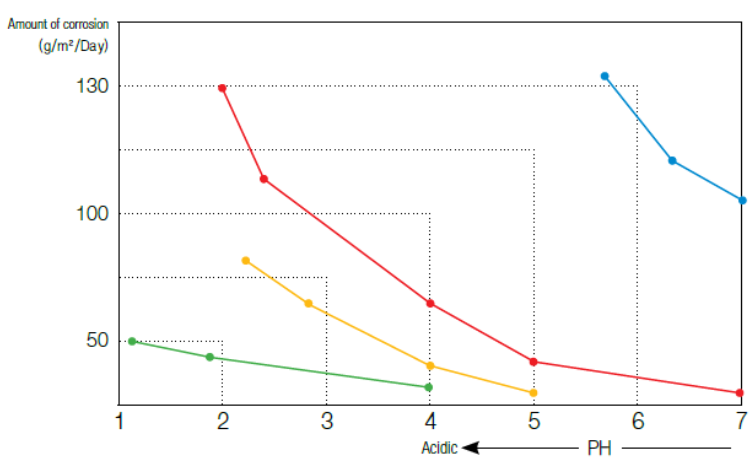

Corrosion resistance

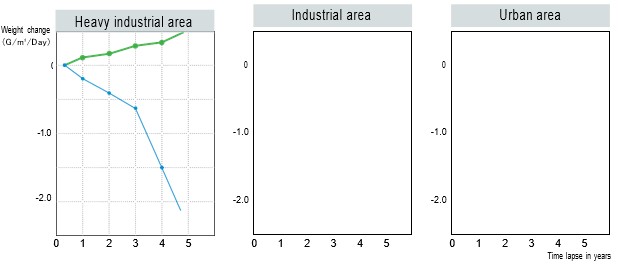

Aluminized steel also forms a thin layer of oxides & hydroxides in the presence of air as well as water. Finally, this makes it resistant to corrosion. In fact, even in acidic solutions, it shows excellent corrosion resistance as compared to galvanized steel sheets. Besides, the amount of corrosion is in g/m2/day.

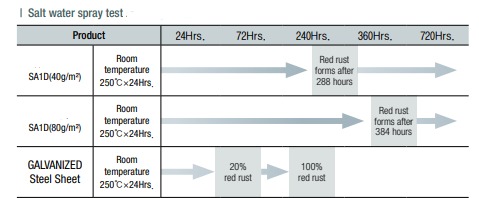

Salt water spray test

Aluminized steel salt water spray test shows excellent corrosion resistance & is proved by the Salt Water Spray Test data. Al shows higher electrode resistance as compared to Fe. As Fe is cathodized, Al prevents corrosion of Fe & acting as a sacrificial anode.

Heat Reflectivity

Aluminized steel has a beautiful surface as well as excellent heat reflectivity, therefore used in manufacture of toasters, gas ranges, oil stoves, gas ovens as well as clothes dryer etc.

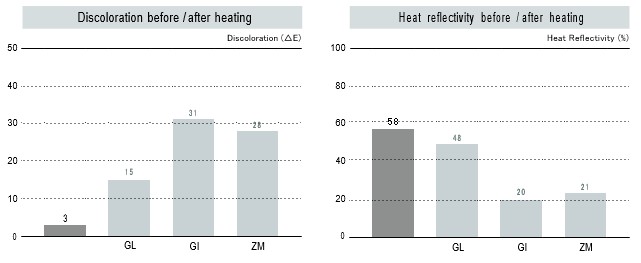

Comparison of with Galvanized Steel (GL), Galvanized Iron (GI) & ZM sheet metals is shown below for Discoloration as well as Heat Reflectivity using parameters: 4000C; 24 hours.

Processability

Aluminized steel has better Processability as compared to cold-rolled sheets. The mechanical properties are as follows:

| Product | Type | Symbol (KS/JIS) | Tensile test | ||

| Yield strength (MPa) | Tensile strength (MPa) | Elongation (%) | |||

| AS | Commercial Quality | SA1C | ≥ 226 | ≥ 294 | – |

| Drawing Quality | SA1D | ≥ 206 | ≥ 284 | ≥ 36 | |

| Deep Drawing Quality | SA1E | ≥ 196 | ≥ 275 | ≥ 40 | |

Paintability

Aluminized steel Can be painted better than galvanized steel sheets by chemical pre-treatment as shown below.

Paints based on the following types can be used: Vinyl Resins, silicone resins, phenolic resin, polyurethane resin & lacquers.

Weatherability

Aluminized steel has excellent resistance in severely corrosive environments like light & heavy industrial areas as well as urban areas. The sheet shows no change in weatherability even if it turns brown in the external environment.

Standard comparison

| Classification | KS D 3544 | JIS G 3314 | ASTM A 463 | DIN EN 10346 |

| Commercial Quality | SA1C | SA1C | CS | DX51D |

| Drawing Quality | SA1D | SA1D | - | DX52D, 53D |

| Deep Drawing Quality | SA1E | SA1E | DDS | DX54D |

| Extra Deep Drawing Quality | - | - | EDDS | DX56D |

Minimum coating weight (double side)

| Coating weight symbol | Minimum coating weight for 3 points on both sides | Minimum coating weight for 1 point on both sides | KS D 3544 | JIS G 3314 | ASTM A 463 | DIN EN 10346 |

| 40 | 40 | 30 | 40 | 40 | T1-13(40) | – |

| 60 | 60 | 45 | 60 | 60 | – | AS 060 |

| 80 | 80 | 60 | 80 | 80 | T1-25(75) | – |

| 100 | 100 | 75 | 100 | 100 | – | AS 100 |

| 120 | 120 | 90 | – | 120 | T1-40(120) | – |

| 160 | 160 | 120 | – | – | – | – |

| Width (W) Thickness(t) | W<1000 | Mark |

| 0.40≤ t <0.60 | ± 0.07 | ± 0.07 |

| 0.60≤ t <1.00 | ± 0.10 | ± 0.10 |

| 1.00≤ t <1.60 | ± 0.13 | ± 0.14 |

| 1.60≤ t <2.30 | ± 0.17 | ± 0.18 |

| 2.30≤ t | ± 0.21 | ± 0.22 |

KS, JIS

| Width (W) Thickness(t) | W≤1500 |

| t≤0.4 | ±0.08 |

0.4| ±0.10 |

|

1.0| ±0.13 |

|

1.5| ±0.15 |

|

2.0| ±0.30 |

|

ASTM

Thickness tolerance

| Thickness(t) | W≤1200 | 1200 |

| T ≤ 0.40 | ±0.05 | ±0.06 |

0.40| ±0.05 | ±0.06 |

|

0.60| ±0.06 | ±0.07 |

|

0.80| ±0.07 | ±0.08 |

|

1.00| ±0.08 | ±0.09 |

|

1.20| ±0.11 | ±0.13 |

|

1.60| ±0.14 | ±0.15 |

|

2.00| ±0.16 | ±0.17 |

|

DIN EN

Minimum coating weight (double side)

| Coating weight symbol | Minimum coating weight for 3 points on both sides | Minimum coating weight for 1 point on both sides | KS D 3544 | JIS G 3314 | ASTM A 463 | DIN EN 10346 |

| 40 | 40 | 30 | 40 | 40 | T1-13(40) | – |

| 60 | 60 | 45 | 60 | 60 | – | AS 060 |

| 80 | 80 | 60 | 80 | 80 | T1-25(75) | – |

| 100 | 100 | 75 | 100 | 100 | – | AS 100 |

| 120 | 120 | 90 | – | 120 | T1-40(120) | – |

| 160 | 160 | 120 | – | – | – | – |

Ks D 3544

| Classification | Symbol | Elongation(%) | Bending | |||

| 0.4≤t<0.6 | 0.6≤t<1.0 | 1.0≤t | Bend Angle | Inner Spacing od Bend | ||

| Commercial Quality | SA1C | - | - | - | 180˚ | 4t |

| Drawing Quality | SA1D | ≧30 | ≧32 | ≧34 | 180˚ | 1t |

| Deep Drawing Quality | SA1E | ≧34 | ≧36 | ≧38 | 180˚ | 1t |

JIS G 3314

| Classification | Symbol | Tensile strength (MPa) | Yield strength (MPa) | Elongation(%) | Bending | ||||

| 0.3≤ t <0.4 | 0.4t<0.6 | 0.6< t≤1.0 | 1.0≤ t | Bend Angle | Inner Spacing od Bend | ||||

| Commercial Quality | SA1C | (≥205) | (≥270) | - | - | - | - | 180˚ | 4t |

| Drawing Quality | SA1D | - | ≥280 | (≥28) | ≥30 | ≥32 | ≥34 | 180˚ | 1t |

| Deep Drawing Quality | SA1E | - | ≥270 | - | ≥34 | ≥36 | ≥38 | 180˚ | 1t |

DIN EN 10364

| Classification | Symbol | Yield strength(MPa) | Tensile strength(MPa) | EL(%) |

| Commercial Quality | DX51D | - | 270~500 | ≥22 |

| Drawing Quality | DX52D | 140~300 | 270~420 | ≥26 |

| DX53D | 140~260 | 270~380 | ≥30 | |

| Deep Drawing Quality | DX54D | 120~220 | 260~350 | ≥34 |

| Extra Deep DrawingQuality | DX56D | 120~180 | 260~350 | ≥39 |

ASTM A 463

| Classification | Symbol | Yield strength(MPa) | EL(%) |

| Commercial Quality | CS Type A | 170~345 | ≥20 |

| CS Type B | 205~345 | ≥20 | |

| CS Type C | 170~380 | ≥15 | |

| Drawing Quality | DDS | 140~240 | ≥32 |

| Deep Drawing Quality | EDDS | 125~205 | ≥38 |

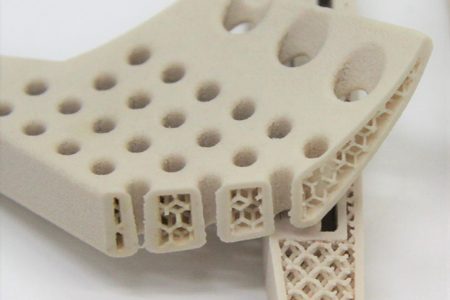

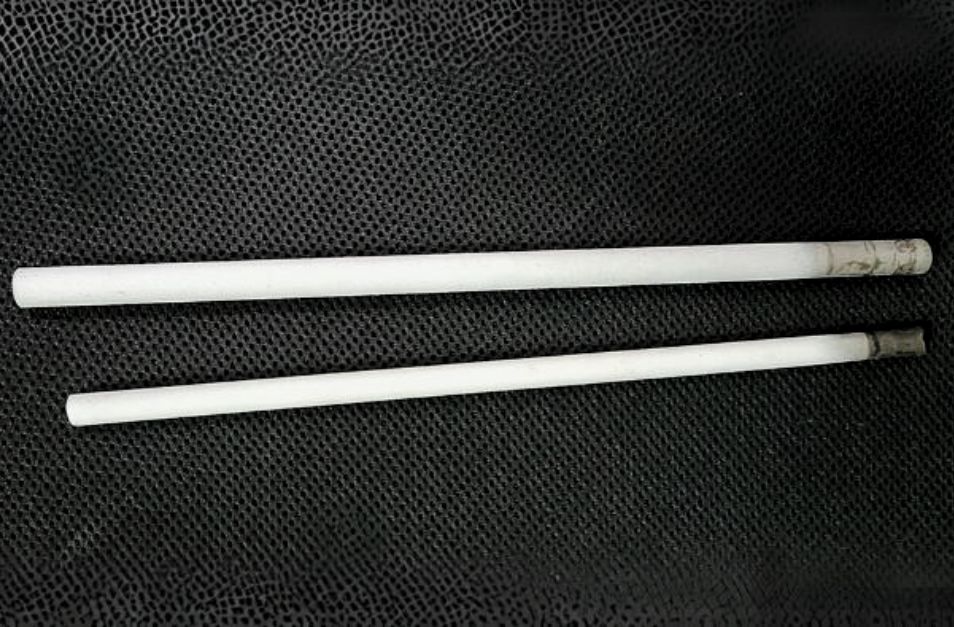

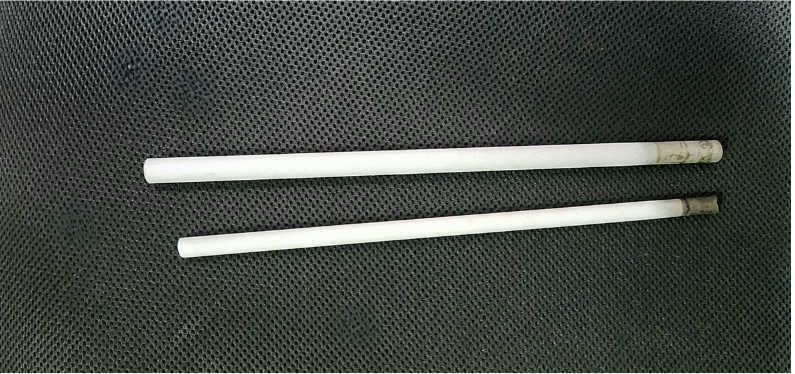

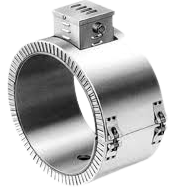

Band heater

Aluminized steel band heater is a type of steel that has been coated with an aluminum-silicon alloy to enhance its properties. Aluminized steel is widely used in the manufacturing of band heaters due to its excellent thermal and corrosion resistance properties. A band heater is a type of heating element that is wrapped around a cylinder or pipe to provide heat. The aluminized steel used in band heaters creates a highly efficient, durable, and cost-effective solution for heating applications. The aluminum coating on the steel provides excellent heat transfer properties, allowing the band heater to maintain a consistent temperature. Band heaters are commonly used in many industries, including plastics, oil and gas, food processing, and packaging. With the use of aluminized steel, band heaters become long-lasting and an effective solution for heating applications.

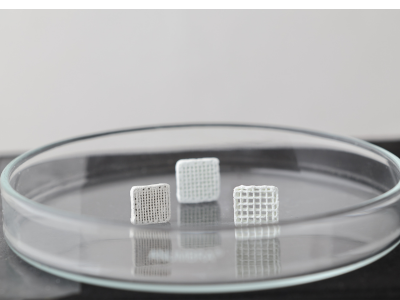

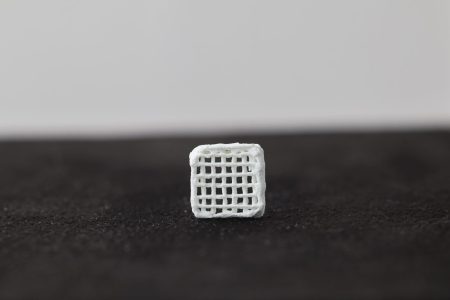

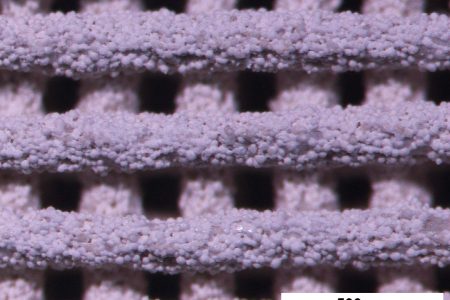

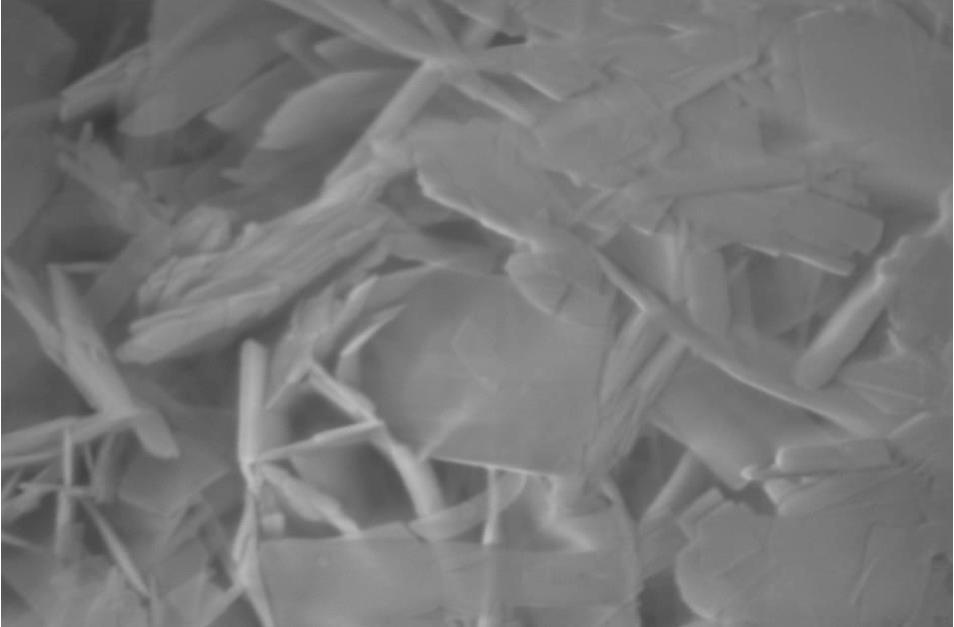

Mica heater

Aluminized steel mica heater is coated with aluminum and is commonly used in automotive exhaust systems, construction materials, and household appliances. Aluminized steel is also used to manufacture mica heaters, thin, flat heaters used for high-temperature applications. Mica heaters consist of a thin sheet of insulation with a heating element sandwiched between two layers of aluminized steel. This design provides excellent heat transfer and protection for the heating element, making mica heaters a popular choice in food processing, medical instruments, aerospace, and plastic industries. By combining aluminized steel with mica heaters, an efficient and reliable heating solution is provided for a wide range of applications.

Gas range

Aluminized steel gas range is a type of cooking appliance that is commonly used in homes and commercial kitchens for preparing meals. It is made with a steel base or frame that is coated with a layer of aluminum to provide a rust-resistant and heat-resistant surface. The heat is typically controlled by knobs or dials on the front of the range, which allow the user to adjust the flame intensity. Aluminized steel gas ranges are popular because of their durability, affordability, and ability to withstand high temperatures.

Microwave oven

Aluminized steel microwave oven is a type of microwave oven that is made of a combination of steel and aluminum. The steel provides durability and strength, while the aluminum coating helps to reflect the microwaves inside the cavity of the oven. This allows for even cooking and heating of food items, as the microwaves are evenly distributed throughout the cavity.

Dryer

Aluminized steel dryer is a type of clothes dryer that features a drum made of aluminized steel. The aluminized steel provides better protection against rust and wear than regular steel. The dryer is designed to spin wet clothes inside the drum while heated air is blown through them, evaporating the water and leaving the clothes dry. Aluminized steel dryers are very durable, and they can endure high temperatures without warping or cracking. Additionally, aluminized steel dryers are very quiet and produce less noise than other types of dryers. They are a popular choice for households that want a reliable and efficient way to dry clothes quickly and conveniently.

Exhaust

Aluminized steel exhaust system Improved car exhaust systems are now required to meet Bharat Stage VI emissions standards. Aluminized steel Type 1 is an ideal material for coating exhaust systems as it can withstand high temperatures and thereby control emissions, supporting compliance with global emission regulations.

Heat shield

Aluminized steel heat shields sensitive automobile parts from engine and exhaust-generated heat. With 80% reflectivity, it acts as a cost-effective heat shield that remains shiny up to 4000C. Shields are placed under car parts and around the engine to prevent overheating.

Heat shield

Aluminized steel heat shields sensitive automobile parts from engine and exhaust-generated heat. With 80% reflectivity, it acts as a cost-effective heat shield that remains shiny up to 4000C. Shields are placed under car parts and around the engine to prevent overheating.

Fuel tanks

Aluminized steel Fuel tanks made of cold rolled and mild steel can corrode due to impurities in petrol, diesel, and bio-diesel. This leads to rust particles floating in the fuel which adversely affects the engine and automobile performance. The use of aluminized steel is recommended as it is strong and resistant to corrosion by almost all petroleum and synthetic fluids.

Hose Pipe

Aluminized steel hose pipes are flexible tubing made with a steel core coated or laminated with aluminum, resistant to heat and corrosion. They’re used in chemical processing, vehicles’ exhaust systems, and industrial manufacturing. Hot-dipping or thermal spraying applies the aluminum. These lightweight pipes are durable, withstand high pressure and temperatures, and have high thermal conductivity. They’re preferred over other pipes due to their resistance to rust, oxidation, and other forms of corrosion, making them ideal for applications where heat transfer is essential. Aluminized steel hose pipes offer a reliable and cost-effective solution and meet the demands for durability, flexibility, resistance to corrosion and heat.

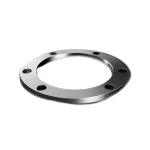

Gasket

Aluminized steel gasket is a type of sealing material used to create a tight seal between two surfaces in machinery, engines, and other industrial applications. This type of gasket typically consists of a steel core surrounded by a layer of aluminum on both sides. The aluminum layer provides excellent resistance to corrosion, while the steel core provides strength and durability. The gasket functions by compressing between the two surfaces to fill any imperfections and provide a seal that prevents leaks and loss of pressure. Aluminized steel gaskets are commonly used in high-temperature and high-pressure environments, such as in exhaust systems, engines, and industrial boilers. They are also useful in applications where resistance to corrosion and oxidation is essential.

Aluminized Steel Type 1 - Our Product Range

Aluminized Steel Type 1 - Related Products

- International

- Domestic

- Asia

- North America

- South America

- Europe

- Africa

- Australia

Asia

North America

Europe

Africa

Australia

-

East India

- West India

- North India

- South India

- Union Territories of India

Balod, Baloda Bazar, Balrampur, Bastar, Bemetara, Bijapur, Dantewada, Dhamtari, Durg, Gariaband, Janjgir Champa, Jashpur, Kabirdham, Kanker, Kondagaon, Korba, Koriya, Mahasamund, Mungeli, Narayanpur, Raigarh, Raipur, Rajnandgaon, Sukma, Surajpur, Surguja, Moudhapara, Birgoan, Lalpur, Nahar Para, Devpuri, Bilaspur, Rajnandgaon, Dagori , Tilda, Lara, Silphari , Siltara, Champa, Jamul.

Angul, Boudh (Baudh), Balangir, Bargarh, Balasore (Baleswar), Bhadrak, Cuttack, Deogarh (Debagarh), Dhenkanal, Ganjam, Gajapati, Jharsuguda, Jajpur, Jagatsinghapur, Khordha, Keonjhar (Kendujhar), Kalahandi, Kandhamal, Koraput, Kendrapara, Malkangiri, Mayurbhanj, Nabarangpur, Nuapada, Nayagarh, Puri, Rayagada, Sambalpur, Subarnapur (Sonepur), Sundargarh, Kataka, Rayagada,.

Alipurduar, Bankura, Birbhum, Cooch Behar, Dakshin Dinajpur, Darjeeling, Hooghly, Howrah, Jalpaiguri, Jhargram, Kalimpong, Kolkata, Malda, Murshidabad, Nadia, North 24 Parganas, Paschim Bardhaman, Paschim Medinipur, Purba Bardhaman, Purba Medinipur, Purulia, South 24 Parganas, Uttar Dinajpur, Tangra, Haldia, Bilkanda, Bajitpur, Rameshwerpur, Barrackpore, Dasnagar, Bagh, Dankunibil, Nandal, Sahalalpur, Domjur, Rajhat, Tegharia, Narendra Chandra Dutta Sarani, Chandni Chawk, B.B.D. Bagh,Bowbazar, Maheshtala, Asansol, Belghoria, Tikiapara,

East Sikkim, North Sikkim, South Sikkim, West Sikkim, Gangtok, Mangan, Namchi, Geyzing.

Bokaro, Chatra, Deoghar, Dhanbad, Dumka, East Singhbhum, Garhwa, Giridih, Godda, Gumla, Hazaribagh, Jamtara, Khunti, Koderma, Latehar, Lohardaga, Pakur, Palamu, Ramgarh, Ranchi, Sahebganj, Seraikela, Simdega,West Singhbhum, Aditpapur, Gamharia, Ahirtoli, Tatisilwai, Gamharia, Hazaribagh, haranganj, Kumhartoli, Pandra, Bokaro Steel City, Argora, Delatoli, Medininagar, Dhanbad, Hatia, Jumala, Tensera, Tudupana, Kokar, Namkum, Tatisilwai, Chapawar, Koilari, Sarwal, Kulhi, Burmu, Patratu, Barhi, Sikri, Daltonghanj, Koderma, Belchampa, Lohardagga, Barghi, Babhani, Sikri, Belchampa.

Baksa, Barpeta, Biswanath, Bongaigaon, Cachar, Charaideo, Chirang, Darrang, Dhemaji, Dhubri, Dibrugarh, Dima Hasao, Goalpara, Golaghat, Hailakandi, Hojai, Jorhat, Kamrup Metropolitan, Kamrup, Karbi Anglong, Karimganj, Kokrajhar, Lakhimpur, Majuli, Morigaon, Nagaon, Nalbari, Sivasagar, Sonitpur, South Salmara-Mankachar, Tinsukia, Udalguri, West Karbi Anglong, Silchar, North Guwahati, Bijni, Margherita, Barpeta Road, Sonari, Kharupetia, Dhekiajuli, Jagiroad, Guwahati, Lanka, Tezpur, Lumding, Amguri, Ambikapur, Chabua, Lakhipur, Gohpur, Jogighopa, Badarpur, Duliajan, Moran, Diphu, Hamren, Abhayapuri, Marigaon, Rangapara, New Bongaigaon Railway Colony, Bokajan, Mangaldai, Haflong, Numaligarh, Silchar Part-X, Doboka, Digboi Oil Town, Sibsagar, Biswanath Chariali, Dergaon, Bokokhat, Bilasipara, Silapathar, Dispur.

Changlang, East Kameng, East Siang, Lohit, Lower Subansiri, Papum-Pare, Tawang, Tirap, Upper Siang, Upper Subansiri, West Siang, Anjaw, Lower Dibang Vally, Kurung Kumey, Namsai, Ziro, West Kameng, Naharlagun, Papum Pare, Pasighat, Tezu, Basar, Itanagar, Roing, Khonsa, Doimukh, Namsai, Chimpu, Pasighat, Itanagar, Namsai.

Dhalai, North Tripura, West Tripura, South Tripura, Ambassa, Kailasahar, Udaipur, Agartala, Khowai, Indranagar, Kanchanpur, Kailasahar.

Araria, Arwal, Aurangabad, Banka, Begusarai, Bhagalpur, Bhojpur, Buxar, Darbhanga, East Champaran, Gaya, Gopalganj, Jamui, Jehanabad, Khagaria, Kishanganj, Kaimur, Katihar, Lakhisarai, Madhubani, Munger, Madhepura, Muzaffarpur, Nalanda, Nawada, Patna, Purnia, Rohtas, Saharsa, Samastipur, Sheohar, Sheikhpura, Saran, Sitamarhi, Supaul, Siwan, Vaishali, West Champaran, Bettiah, Hajipur, Dumra, Arrah, Motihari, Bhabua, Bihar Sharif, Sasaram, Chhapra, Dumra,Sitamarhi, Piro, Jogbani, Bihariganj, Raxaul, Daudnagar, Hisua, Chakia, Nirmali, Motipur, Ramnagar, Asarganj, Ghoghardiha, Bikramganj, Dinapur Cantonment, Nokha, Dehri, Kanti, Jagdispur, Teghra, Jhanjharpur, Habibpur, Mairwa, Areraj, Dalsingh Sarai, Amarpur, Jamalpur, Dhaka, Barh, Masaurhi, Mohiuddinagar, Naugachhia, Maharajganj, Chhatapur, Forbesganj, Bihar, Rajgir, Marhaura, Chanpatia, Barhiya, Narkatiaganj, Lalganj, Jaynagar, Islampur, Phulwari, Ara, Bodh Gaya, Mokama, Colgong, Ghrounda, Deedarganj , Chhoti Pahari, Chapra, Hajipur, Mohanbariam, Madhopara, Gehumi, Kaghzi Mohalla.

East Garo Hills, East Khasi Hills, Jaintia Hills,Ri Bhoi,South Garo Hills,West Khasi Hills, Williamnagar, Shillong, Jowai, Nongpoh , Baghmara, Tura, Nongstoin, West Garo Hills, Shillong Cantonment, Jawai, Nongthymmai.

Thoubal, Imphal East, Imphal West, Senapati, Ukhrul, Chandel, Churachandpur, Tamenglong, Nambol, Imphal, Jiribam, Bishnupur, Moreh, Kakching.

Aizawl, Kolasib, Lawngtlai, Lunglei, Mamit, Saiha, Serchhip, Champhai.

Dimapur, Kiphire, Kohima, Longleng, Mokokchung, Mon, Peren, Phek, Tuensang, Wokha, Zunheboto, Noklak.

Ahmednagar, Akola, Amravati, Aurangabad,v Beed, Bhandara, Buldhana, Chandrapur, Dhule, Gadchiroli, Gondia, Hingoli, Jalgaon, Jalna, Kolhapur, Latur, Mumbai, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Palghar, Parbhani, Pune, Raigad, Ratnagiri, Sangli, Satara, Sindhudurg, Solapur, Thane, Wardha, Washim, Yavatmal, Kalamboli, Taloja, Vasai, Vashi, Mira Bhayandar, Bhiwandi, Ulhasnagar, Ambarnath, Panvel, Degaon , Kupwad, Waluj , Avadhan , Tarapur, Boisar, Pimpri, Chinchwad , Satpur, Ambad, Sinnar, Butibori, Kagal , Gokul Shirgaon, Shiroli, Akola, Mahad, Rabale, Turbhe, Kalyan, Chandrapur, Lote, Beed. Osnambad, Satna, Nagothane.

Ahmedabad, Amreli, Anand, Aravalli, Banaskantha, Bharuch, Bhavnagar, Botad, Chhota Udaipur, Dahod, Dang, Devbhoomi Dwarka, Gandhinagar, Gir Somnath, Jamnagar, Junagadh, Kutch, Kheda, Mahisagar, Mehsana, Morbi, Narmada, Navsari, Panchmahal, Patan, Porbandar, Rajkot, Sabarkantha, Surat, Surendranagar, Tapi, Vadodara, Valsad, Palanpur, Veraval, Bhuj, Lunavada, Rajpipla, Godhra, Himmatnagar, Vyara, Dahej, Sanand ,Vani, Vatwa, Dhandhuka, Dholka, Viramgam, Kathawada, Odhav, Naroda, Sankheda, Sankheda, Dabhoi, Ranoli, Limbda, Por Ramangamdi, Nandesari, Makarpura, Vaghodia, Savli, Thasra, Kapadwanj, Matar, Nadiad, Balasinor, Sojitra, Umreth, Petlad, Borsad, Khambat, V.U. Nagar, Bhat,Dehgam, Mansa, Ranasan, Gozaria, Pardi, Bhilad, Umbergaon, Sarigam , Vapi, Unai, Bilimora, Dhrol, Bhatia, Bhanvad, Jamkhambhalia, Arambhada, Kotda-Sangani, Paddhari, Malia, Jasdan, Bhaktinagar, Jetpur, Wankaner, Morbi, Dhoraji, Gondal, Rafaleshwar, Kuvadawa, Aji, Lodhika, Valod, Khatodara, Bardoli, Nizarm, Olpad, Katargam, Doswada, Pandesaram, Hazira, Sachin, Ichchapore, Jafrabad, Liliya, Rajula, Babra, Damnagar, Amrelim, Babra, Vallabhipur, Dhasa, Botad, Vitthalwadi, Shihor, Palitana, Mahuva, Shihor, Vertej, Alang, Chitra, Sihori, Ambaji, Radhanpur, Chandisar, Mundra, Madhapur, Anjar, Mandvi, Vagra, Jambusar, Hansot, Panoli, Nabipur, Dungari, Valia, Naldhari, Kanerao, Dodwada, Kondh, Atali-Kaladra, Ankleshwar, Jhagadia, Tilakwada, Sagbara, Dediapada, Rajpipla, Visavadar, Veraval, Sutrapada, Porbandar, Miyani, Sayla, Chotila, Lakhtar, Halvad, Thangadh, Dhangadhra, Limbdi, Bamanbore, Kukarwada, Balisana, Kheralu, Visnagar, Vijapur, Kalol, Kadi, Chhatral, Patan, Chanasma, Lanva, Sidhpur, Jambughoda, Shahera, Godhra, Halol, Devgadhbaria, Malpur, Idar, Modasa, Himatnagar, Talod, Pimpri, Rakhial, Odhav, Sarkhej, Dhanera, Alang, Dharangadhra, Deea, Gandhidham, Karjan, Vartej, Kapadwanj, Pardi, Kanjari, Kaliawadi, Mithapur, Bhachau, Patan, Tapi, Sayla, Amroli.

North Goa, South Goa, Mapusa, Bicholim, Panaji, Bardez, Tiswadi, Bicholim, Sattari, Pernem, Mormugao, Ponda, Quepem, Margao and Dharbandora. Salcete, Sanguem, Canacona, Bethora, Bicholim, Canacona, Colvale, Corlim, Cuncolim, Dharbandoda, Honda, Kakoda, Kundaim, Latambarcem, Madkaim, Mapusa, Margao Panchwadi, Pilerne, Pissurlem, Quittol, Sancoale, Sanguem, Shiroda, Thivim, Tuem,Verna, Pilerna, Porvorim,

Bilaspur, Chamba, Hamirpur, Kangra, Kinnaur,Kullu,Lahaul & Spiti, Mandi, Shimla , Sirmaur, Solan, Una, Baddi, Sheetalpur , Sundar Nagar, Sirmour, Pataliyon, Una, Indora, Bari, Damtal, Mehatpur, Gagret, Parwano, Barotiwala, Shamshi, Nagrotu Bagwan,Sansar Pur Tera, Solan, Mandi, Hamirpur, Shogi, Raga-Ka-Bagh, Ambi, Taliwala, Keylong.

Amritsar, Barnala, Faridkot, Fatehgarh Sahib, Firozpur, Fazilka, Gurdaspur, Hoshiarpur, Ludhiana,, Moga, Sri Muktsar Sahib, Pathankot, Patiala, Rupnagar, Sahibzada Ajit Singh Nagar, Sangrur, Shahid Bhagat Singh Nagar, Taran Taran, Dhilwan, Dasuya, Dinanagar, Karoran, Samrala, Malaut, Kurali, Mandi Gobindgarh, Jaitu, Nabha, Payal, Balachaur, Muktsar, Moonak, Khamanon, Batala, Bassi Pathana, Guru Har Sahai, Bhadur, Sahnewal, Lalru, Sanaur, Longowal, Jagraon, Sardulgarh, Phillaur, Anandpur Sahib, Mohali, Nawanshahr, Banga, Dera Bassi, Bhikhi, Malerkotla, Doraha, Garhshankar, Kharar, Sirhind, Shahkot, Zirakpur, Khanna, Rampura, Ludhiana, Mansa, Dhuri, Makhu, Amloh, Urmar Tanda, Raman, Goraya, Jalandhar Cantonment, Hoshiarpur, Kartarpur, Bhuch, Malout, Rajpura, Kotkapura, Sunam, Giddarbaha, Dirba, Firozpur Cantonment, Dhariwal, Morinda, Naya Nangal, Hariana, Nakodar, Phagwara, Machhiwara, Ajnala, Sultanpur Lodhi, Tarn Taran, Maur, Zira, Alawalpur, Ghagga, Kot Kapura, Kapurthala, Pattran, Jalalabad, Bagh Purana, Bathinda, Nawashahr, Budhlada, Munak, Bhabat, Bhawanigarh, Abohar, Hajipur, Ahmedgarh, Sujanpur, Samana, Jalandhar, Sahib, Gurdaspur, Nangal,, Mukerian, Talwandi Bhai, Lehra Gaga.

Pithoragarh,Uttarkashi, Rishikesh Cantonment, Rishikesh, Dehradun, Bhim Tal, Mahua Kheraganj, Khatima, Kausani, Bageshwar, Kashipur, Sitarganj, Srinagar, Dehrakhas, Tehri, Haridwar, Narendranagar, Nainital, Vikasnagar, Kotdwara, Ramnagar, Masuri, Rurki, Roorkee, Udham Singh Nagar, Laksar, Kaladungi, Sultanpur, Almora, Manglaur, Kichha, Chamoli and Gopeshwar, Gadarpur, Chakrata, Champawat, Lalkuan, Rudraprayag, Rudrapur, Jaspur, Haldwani, Ranipur, Ranikhet, Pauri, Bazpur, Tanakpur, Chamoli, Pauri Garhwal.

Bhiwani, Charkhi Dadri, Faridabad, Fatehabad, Gurugram, Hisar, Jhajjar, Jind, Kaithal, Karnal, Kurukshetra, Mahendragarh, Nuh, Palwal, Panchkula, Panipat, Rewari, Rohtak, Sirsa, Sonipat, Yamunanagar, Ladwa, Indri, Punahana, Siwani, Asandh, Raipur Rani, Ateli, Barwala, Kheri Sampla, Hodal, Ratiya, Kalka, Narayangarh, Uklana Mandi, Bahadurgarh, Tauru, Gohana, Rania, Pundri, Dharuhera, Ballabgarh, Pehowa, Gurgaon, Ghraunda, Tohana, Kanina, Narwana, Narnaund, Gannaur, Shahabad, Pinjaur, Dabwali, Chita, Samalkha, Hansi, Safidon, Taraori, Kharkhoda, Bawal, Thanesar, Kalanwali, Ellenabad, Loharu, Jagadhri, Radaur, Nilokheri, Maham, Kundli, Bilaspur, Sohna, Ambala Cantt, Narnaul, Farrukhnagar, Firozpur Jhirka, Julana, Beri,Ambala

Ringas, Sirohi, Jhalawar, Bhasawar, Khairthal, Didwana, Bari Sadri, Napasar, Chittorgarh, Kherwara Chhaoni, Kota, Ratangarh, Bharatpur, Barmer, Chhabra, Raisinghnagar, Pushkar, Mangrol, Kumbhalgarh, Bilara, Kuchaman, Chhoti Sadri, Sambhar, Suratgarh, Churu, Asind, Nawalgarh, Kankroli, Raipur, Rajgarh, Aklera, Devgarh, Dausa, Khetri, Pilani, Jaisalmer, Pali, Beawar, Ramgarh, Sangariya, Udpura, Pipar, Nimaj, Vijainagar, Abu Road, Bagru, Bundi, Shahpura, Indragarh, Sumerpur,Balotra, Baswa, Sunel, Gothra, Mount Abu, Surajgarh, Sujangarh, Pratapgarh, Ratan Nagar, Karauli, Dholpur, Chirawa, Bali, Marwar, Gangapur, Ladnun, Hindaun, Swaroopganj, Nathdwara, Deoli, Jhunjhunun, Rajsamand, Kapasan, Kishangarh, Rani, Nasirabad, Bhadra, Neemrana, Bandikui, Jaiselmer, Bikaner, Rawatbhata, Amet, Salumbar, Jhalrapatan, Falna, Rawatsar, Taranagar, Sagwara, Neem Ka Thana, Lakheri, Begun, Padampur, Dungarpur, Udaipur, Chomun, Basi, Phalodi, Pokaran, Bahror, Sardarshahr, Sikar, Jodhpur, Anupgarh, Lachhmangarh, Makrana, Chhipa Barod, Bhinmal, Kekri, Bari, Bhilwara, Jaitaran, Sriganganagar, Nawa, Kuchera, Alwar, Pilibanga, Mandawar, Kaman, Niwai, Pindwara, Jalore, Merta, Newa Talai, Sheoganj, Sojat Road, Hanumangarh, Sawai Madhopur, Ramganj Mandi, Fatehnagar, Kot Putli, Nokha, Nagar, Baran, Nohar, Bhawani Mandi, Ajmer, Nimbahera, Sojat, Malpura, Lalsot, Jaipur, Rajakhera, Bijoliya Kalan, Nagaur, Madanganj, Bhawri, Ganganagar, Raniwara, Mundwa, Sadulshahar, Sadri, Tijara, Phulera, Fatehpur, Banswara, Bhiwadi, Bayana, Sanchor, Tonk.

Aligarh, PrayagRaj, Ambedkar Nagar, Amroha, Auraiya, Azamgarh, Badaun, Bahraich, Ballia, Balrampur, Banda District, Barabanki, Bareilly, Basti, Bijnor, Bulandshahr, Chandauli(Varanasi Dehat), Chitrakoot, Deoria, Etah, Etawah, Faizabad, Farrukhabad, Fatehpur, Firozabad, Gautam Buddha Nagar, Ghaziabad, Ghazipur, Gonda, Gorakhpur, Hamirpur, Hapur District, Hardoi, Hathras, Jaunpur District, Jhansi, Kannauj, Kanpur Dehat, Kanpur Nagar, Kasganj, Kaushambi, Kushinagar, Lakhimpur Kheri, Lalitpur, Lucknow, Maharajganj, Mahoba, Mainpuri, Mathura, Mau, Meerut, Mirzapur, Moradabad, Muzaffarnagar, Pilibhit, Pratapgarh, Rae Bareli, Rampur, Saharanpur, Sant Kabir Nagar, Sant Ravidas Nagar, Sambhal, Shahjahanpur, Shamli, Shravasti, Siddharthnagar, Sitapur, Sonbhadra, Sultanpur, Unnao, Varanasi (Kashi), Allahabad, Amethi, Bagpat, Baheri, Bilsi, Bilaspur, Maghar, Chandausi, Mubarakpur, Palia Kalan, Sadabad, Sahanpur, Jalaun, Lakhimpur, Kurara, Anpara, Gopiganj, Chhata, Sandila, Harraiya, Jewar, Robertsganj, Ramkola, Khekra, Bharthana, Kiratpur, Fatehabad, Sikandra Rao, Jyotiba Phule Nagar, Nautanwa, Jhansi Cantonment, Chilkana Sultanpur, Bangarmau, Usawan, Jais, Tilhar, Fatehpur Chaurasi, Deoband, Khatauli, Rudarpur, Beswan, Kanpur, Tundla, Nawabganj, Kerakat, Jalalabad, Aliganj, Dibiyapur, Purdil Nagar, Sirsaganj, Orai, Biswan, Dhanaura, Shikarpur, Behat, Hasanpur, Sikandarabad, Gautam Buddh Nagar, Modinagar, Nihtaur, Chitrakut Dham, Nichlaul, Khamaria, Bikapur, Jalesar, Loni, Barhani, Musafirkhana, Jasrana, Jansath, Varanasi, Jalalpur, Vrindavan, Kota, Sikandra, Gajraula, Khalilabad, Beniganj, Sardhana, Babrala, Bahjoi, Kundarki, Puranpur, Siyana, Baraut, Phaphund, Agra, Rampura, Ramnagar, Muradnagar, Dhampur, Pilkhuwa, Najibabad, Bilsanda, Dudhinagar, Gola Gokarannath, Greater Noida, Mathura Cantonment, Bindki, Kosi Kalan, Ganj Muradabad, Nagina, Bhatpar Rani, Alapur, Prayagraj Cantonment, Mankapur, Manikpur, Sahaswan, Bilari, Chandpur, Varanasi Cantonment, Bisalpur, Faizabad Cantonment, Bidhuna, Aurangabad, Fatehgarh, Kalpi, Lalganj, Renukut, Bisauli, Dibai, Karhal, Bilhaur, Sherkot, Nakur, Rasra, Seohara, Safipur, Hapur, Daurala, Kishni, Anupshahr, Obra, Rath, Dasna, Tanda, Gunnaur, Barva Sagar, Konch, Mauranipur, Jaunpur, Kishanpur, Bareilly Cantonment, Thakurdwara, Shahganj, Kunda, Ayodhya, Bulandshahar, Mawana, Miranpur, Kanth, Kharkhoda, Budaun, Gursahaiganj, Bhinga, Colonelganj, Zamania, Pandit Deendayal Upadhyay Nagar, Chandauli, Sirsa, Bhadohi, Sidhpura, Rae Bareilly, Karnawal, Sarsawan, Noida, Gyanpur, Shikohabad, Bhongaon, Shahjahanpur Cantonment, Gangoh, Gokul, Khurja, Hata, Sahibabad, Patti, Gulaothi, Anandnagar, Fatehpur Sikri, Chunar, Ghosia Bazar, Mursan, Pahasu, Nizamabad, Agra Cantonment, Kheri, Hyderabad, Kairana, Banda, Dadri.

Balod, Baloda Bazar, Balrampur, Bastar, Bemetara, Bijapur, Bilaspur, Dantewada, Dhamtari, Durg, Gariaband, Janjgir-Champa, Jashpur, Kabirdham, Kanker, Kondagaon, Korba, Koriya, Mahasamund, Mungeli, Narayanpur, Raigarh, Raipur, Rajnandgaon, Sukma, Surajpur, Surguja, Pathalgaon, Dongragarh, Bilha, Kharsia, Saraipali, Mahendragarh, Tildanewra, Jashpurnagar, Champa, Khairagarh, Sarajpur, Bhatapara, Bagbahara, Kurud, Bhilai, Pendra, Baloda, Jagdalpur, Katghora, Sarangarh, Kawardha, Pithora, Ramanuj Ganj, Kumhari, Telgaon, Chirmiri, Bemetra, Kota, Ambikapur, Dongargaon, Sakti, Urla, Charoda.

Agar Malwa, Alirajpur, Anuppur, Ashoknagar, Balaghat, Barwan, Betul, Bhind, Bhopal, Burhanpur, Chhatarpur, Chhindwara, Damoh, Datia, Dewas, Dhar, Dindori, East Nimar, Guna, Gwalior, Harda, Hoshangabad, Indore, Jabalpur, Jhabua, Katni, Mandla, Mandsaur, Morena, Narsinghpur, Neemuch, Niwari, Panna, Raisen, Rajgarh, Ratlam, Rewa, Sagar, Satna, Sehore, Seoni, Shahdol, Shajapur, Sheopur, Shivpuri, Sidhi, Singrauli, Tikamgarh, Ujjain, Umaria, Vidisha, West Nimar, Agar, Khandwa, Khargone, Sukhlia, Loha Mandi, Pithampur, Palda, Narmadapuram, Lasudia , Budasa, Patan, Shahpur, Sonkatch, Pachmarhi, Birsinghpur, Depalpur, Bagli, Parasia, Maksi, Mau, Sarangpur, Malaj Khand, Garoth, Begamganj, Khetia, Machalpur, Barwani, Biaora, Joura, Shahpura, Maihar, Kailaras, Jawad, Multai, Mangawan, Anjad, Sagar Cantonment, Beohari, Jaora, Panagar, Gohad, Karera, Pipliya Mandi, Amarpatan, Gormi, Sihora, Barwaha, Jirapur, Khujner, Manasa, Pichhore, Rajpur, Rampura, Maheshwar, Manawar, Katangi, Bagh, Kotma, Babai, Nalkheda, Alot, Khirkiya, Sanchi, Sitamau, Gairatganj, Malhargarh, Shamgarh, Dabra, Ichhawar, Gadarwara, Vijayraghavgarh, Basoda, Bamaniya, Nagod, Dhamnod, Shujalpur, Rau, Nepa Nagar, Kukshi, Rahatgarh, Betul Bazar, Banda, Pipariya, Udaipura, Badnagar, Bina-Etawa, Mhow, Khajuraho, Amarwara, Berasia, Sendhwa, Mandleshwar, Khurai, Sultanpur, Khilchipur, Jabalpur G.C.F, Baraily, Sausar, Tarana, Malanpur, Jabalpur Cantonment, Badnawar, Petlawad, Bijuri, Timarni, Sironj, Sohagpur, Mandideep, Kareli, Tekanpur, Harsud, Bhainsdehi, Pandhurna, Ashta, Hanumana, Ratlam Kasba, Khategaon, Itarsi, Kasrawad, Ganjbasoda, Chanderi, Rampur Baghelan, Bina Railway Colony, Kurwai, Sanawad, Chichli, Kothi, Nagda, Baihar, Indergarh,,

Perundurai, Thirumazhisai, Melur, Cuddalore, Theni Allinagaram, Kallakkurichi, Sayapuram, Agaram, Sivakasi, Thiruvithankodu, Maraimalai Nagar, Madhavaram, Vadalur, Musiri, Pudukkottai , Kundrathur, Srivaikuntam, Surandai, Bargur, Sholinganallur, Kodambakkam, Palladam, Mulanur, Punjaipugalur, Kelambakkam, Minambakkam, Pennagaram, Kotagiri, Jalakandapuram, Hosur, Bhavani, Tiruchchendur, Punjai Thottakurichi, Vadakarai Kizhpadugai, Ettaiyapuram, Ganapathipuram, Panruti, Ramapuram, Arcot, Vaniyambadi, Mudukulathur, Dhalavoipuram, Gingi, Kadayal, Ayyampettai, Natrampalli, Anaimalai, Kallidaikurichchi, Vadamadurai, Karaikkudi, Pernambut, Kamayagoundanpatti, Vijayapuri, Palayamkottai, Minjur, Thanjavur, Attur, Neyveli, Gandhi Nagar, Dharmapuri, Maduranthakam, Ulundurpettai, Auroville, Vaithiswarankoil, Paramakkudi, Kolachal, Kangayam, Kamuthi, Usilampatti, Vadakku Valliyur, Aralvaimozhi, Belur, Kadathur, Kariamangalam, Inam Karur, Odaiyakulam, Nagapattinam, Udankudi, Arimalam, Mallapuram, Pattiviranpatti, Tirupur, Kaliyakkavilai, Iluppur, Coonoor, Kariapatti, Uttamapalaiyam, Dharapuram, Annur, Vasudevanallur, Ariyalur, Kulithalai, Avadi, Manapparai, Ambasamudram, Tharangambadi, Athanur, Rameswaram, Taramangalam, Sankarankoil, Udagamandalam, Natham, Theni, Kumbakonam, Vellakoil, Kumarapuram, Mayiladuthurai, Alwar Tirunagari, Thiruvalam, Zamin Uthukuli, Coimbatore, Nasiyanur, Chennai, Namakkal, Pallipalaiyam, Vandavasi, Kelamangalam, Kottur, Madurai, Tiruvottiyur, Idappadi, Kalavai, Tiruvallur, Thirunirmalai, Mahabalipuram, Alangulam, Gudiyattam, Vikravandi, Perambalur, Singaperumalkoil, Kovilpatti, Vengavasal, Vilapakkam, Anthiyur, Karumathampatti, Thiruporur, Swamimalai, Madukkarai, Arantangi, Manavalakurichi, Pammal, Urapakkam, Valangaiman, Nagercoil, Singampuneri, Madippakkam, Kinathukadavu, Tirumangalam, Mangadu, Tirupattur, Harur, Puliyankudi, Pollachi, Thuthipattu, Perungalathur, Dindigul, Omalur, Komarapalayam, Thiruvarur, Parangippettai, Kambam, Pallipattu, Acharapakkam, Peraiyur, Sirumugai, Rasipuram, Srirangam, Virudhachalam, Adyar, Thisayanvilai, Polur, Vandalur, Nanguneri, Sattur, Tiruchengode, Aruppukkottai, Kuzhithurai, Kunnathur, Tindivanam, Devakottai, Alangudi, Uthangarai, Kottakuppam, Ranipet, Sankari, Sathyamangalam, Nallur, Sholingur, Tiruverambur, Sirkali, Ramanathapuram, Kolathur, Nannilam, Athani, Karur, Chennimalai, Kattuputhur, Salem, Sivagiri, Nilgiris, Kaveripattinam, Gobichettipalayam, Periyakulam, Cheyyar, Ambur, Chinalapatti, Papanasam, Tiruvannamalai, Aravakurichi, Mallur, Chinna Salem, Sivaganga, Erode, Udumalaipettai, Anakaputhur, Palakkodu, Arni, Maduravoyal, Virudhunagar, Kattumannarkoil, Pudukkottai, Tirupathur, Lalgudi, Tenkasi, Thondamuthur, Chennasamudram, Tirukkoyilur, Arakonam, Sulur, Melvisharam, Kollankoil, Chengalpattu, Ooty, Thiruthangal, Kalugumalai, Udayarpalayam, Krishnagiri, Gummidipoondi, Chembarambakkam, Peravurani, Tiruverkadu, Kayalpattinam, Punjai Puliyampatti, Tuticorin, Kalpakkam, Gangavalli, Srimushnam, Pattukkottai, Saravanampatti, Vilathikulam, Denkanikottai, Muthupet, Thirumalayampalayam, Guduvanchery, Chatrapatti, Madanur, Thuvakudi, Arani, Bhuvanagiri, Perungudi, Kanchipuram, Kodaikanal, Karamadai, Kanyakumari, Mukkudal, Huligal, Nellikkuppam, Panapakkam, Uthiramerur, Shenkottai, Kilvelur, Nilakkottai, Mettur, Kanakkampalayam, Mamallapuram, Gudalur, Thirunindravur, Puliyur, Tiruchirappalli, Uttukkuli, Villupuram, Mannargudi, Nerkunram, Tirunelveli, Manachanallur, Thottiyam, Walajapet, Ponneri, Kumarapalayam, Porur, Jayankondam, Mettupalayam, Valavanur, Vedaranniyam, Vriddhachalam, Srivilliputtur, Pappireddipatti, Orathanadu, Kadayanallur, Manamadurai, Puzhal, Palani, Edaikodu, Annavasal, Adiramapattinam, Oddanchatram, Avinashi, Mylapore, Valasaravakkam, Mattur, Pandamangalam, Chidambaram, Katpadi, Thevaram, Elayirampannai, Sriperumpudur, Madambakkam, Chinnammanur, Bodinayakkanur, Virakeralam, Thiruthuraipundi, Kilakarai, Rajapalayam, Vellore, Kallakurichi, Kanniyakumari, Thoothukudi, Tiruppur, Tiruvarur, Viluppuram, Ambattur, Parrys, Broadway, Guindy, Madhavaram, Padi, Sriperumbudur, Injambakkam, Mudichur, Park town, Sowcarpet, , Vadapalani, Teynampet, Velachery, Mannivakkam Perambur, Thuraipakkam, Tondiarpet.

Adilabad, Bhadradri Kothagudem, Hyderabad, Jagitial, Jangaon, Jayashankar Bhupalapally, Jogulamba Gadwal, Kamareddy, Karimnagar, Khammam, Kumarambheem Asifabad, Mahabubabad, Mahabubnagar, Mancherial district, Medak, Medchal–Malkajgiri, Mulugu, Nagarkurnool, Narayanpet, Nalgonda, Nirmal, Nizamabad, Peddapalli, Rajanna Sircilla, Ranga Reddy, Sangareddy, Siddipet, Suryapet, Vikarabad, Wanaparthy, Warangal Rural, Warangal Urban, Yadadri Bhuvanagiri, Adilabad, Kothagudem, Bhupalpalle, Gadwal, Asifabad, Mancherial, Shamirpet, Sircilla, Shamshabad, Warangal, Bhongir, Secunderabad, Ranigunj, Yellandu, Medchal, Manuguru, Palwancha, Patancheru, Ranga Reddy district, Miryalaguda, Sathupalle, Ramagundam, Bhainsa, Armoor, Narsampet, Ghatkesar, Jagtial, Zahirabad, Koratla, Tandur, Kodada, Gajwel, Bodhan, Sarapaka, Bhadrachalam.

Anantapur, Chittoor, East Godavari, Guntur, Kadapa, Krishna, Kurnool, Sri Potti Sri Ramulu Nellore, Prakasam, Srikakulam, Visakhapatnam, Vizianagaram, West Godavari, Kakinada, Machilipatnam, Nellore, Ongole, Eluru, Renigunta, Hukumpeta, Chirala, Rajam, Markapur, Kurmannapalem, Suriapet, Madanapalle, Mancheral, Razam, Kanigiri, Pendurthi, Palmaner, Mandapeta, West Godavari Dist., Alampur, Dharmavaram, Narsapur, Tadepalligudem, Pedana, Avanigadda, Ramachandrapuram, Tirvuru, Nandigama, Tadpatri, East Godavari Dist., Peddapuram, Qutubullapur, Gopalapatnam, Uppal Kalan, Bestavaripeta, Pamur, Sirsilla, Pedagantyada, Guti, Puttur, Rameswaram, Kamalapuram, Nagari, Chimakurthy, Kavali, Rajampet, Bapatla, Turangi, Anakapalle, Jammalamadugu, Proddatur, Srikalahasti, Dhone, Penugonda, Narasaraopet, Amur, Tirumala, Vetapalem, Tiruchanur, Palasa, Tuni, Guntakal, Amalapuram, Garacharma, Nandyal, Punganuru, Kuppam, Hindupur, Yemmiganur, Gudur, Sirpur, Rajendranagar, Choutuppal, Salur, Tekkali, Vemalwada, Narayanavanam, Bobbili, Sattenapalle, Mandasa, Gudivada, Adoni, Pulivendla, Chilakaluripet, Uravakonda, Kollapur, Prasantinilayam, Atmakur, Badvel, Trimulgherry, Tenali, Bhimavaram, Nuzvid, Chandur, Karnul, Cuddapah, Kazipet, Ravulapalam, Marturu, Betamcherla, Sulurpeta, Yadagirigutta, Pakala, Nidadavole, Godavarikhani, Repalle, Cumbum, Gannavaram, Nayudupeta, Narsipatnam, Tirupati, Rajahmundry, Palakole, Ajjaram, Samalkot, Kamareddi, Pithapuram, Vijayawada, Chinagantyada, Bapulapadu, Chodavaram, Tanuku, Macherla, Challapalle, Kadiri, Mahabubnagar, Yellamanchili, Akividu, Jaggayyapeta, Gajuvaka, Vinukonda, Kovvur, Singarayakonda, Seetharampuram, Kovur, Andole, Mangalagiri.

Bangalore / Bengaluru , Hubli, Belgaum , Mysuru / Mysore, Shivamogga, Gulbarga, Tumakuru, Davangere, Udupi, Ballari, Bidar, Dharwad , Hampi, Biljapur, Chitradurga, Badami, Hassan, Hosapete, Chikmaglur, Raichur, Gadag, Madikeri, Srirangapatna, Mandya, Bhadravathi, Bagalkot, Karwar, Belur, Uttara Kannada, Pattadakal, Gangavathi, Halebidu, Ranebennur, Hassan, Kolar, Dandeli, Gulbarga, Sringeri, Robertsonpet, Bijapur, Aihole, Manipal, Gadag, Devanahalli, Koppal, Kolar, Manipal, Doddaballapur, Sakleshpur, Karkala.

Kochi, Thiruvananthapuram, Tirvandrum, Kozhikode, Thrissur, Kollam, Kannur, Kottayam, Alappuzha, Palakkad, Munnar , Varkala , Thalassery, Kovalam, Kasaragod, Aluva, Perinthalmanna, Pathanamthitta, chalakuddy, Thodupuzha, Punalur, Tirur, Guruvayur, Kodungallur, Thiruvalla, Malappuram, Muvattupuzha, Kumarakom, Kollam, Tripunithura, Nilambur, Adoor, Kalpetta, Cherthala, Chegannur, Vadakara, Kayamkulam, Ottapalam, Kottarakkara, Vaikom, Ponnani, Kanhangad, Changanacherry, Mattancherry, Kothamangalam, Kalamassery, Koyilandy, Pala, Chavakkad, Perumbavoor, Beypore

Anantnag, Bandipore, Baramulla, Budgam, Doda, Ganderbal, Jammu, Kathua, Kishtwar, Kulgam, Kupwara, Poonch, Pulwama, Rajauri, Ramban, Reasi, Samba, Shopian district, Srinagar, Udhampur, Leh, Kargil, Kishtwar, Shupiyan, Ganderbal,Kartholi, Lassipora, Rangreth, Sopore, Shalteng, Lassipora, Ghatti, Budgam, Trikuta Nagar, Bakshi Nagar, Bishnah, Digiana, Kothi Bagh.

Central Delhi, North Delhi, South Delhi, East Delhi, North East Delhi, South West Delhi, New Delhi, North West Delhi, West Delhi, South Eest Delhi, Daryaganj, Sadar Bazaar, Saket, Preet Vihar, Shahdara, Palam, Connaught Place, Kanjhawala, Rajouri Garden, Defence Colony,Ajmeri Gate, Rohini, Nawada, Anand Parbat, Mundka.

South Andaman, North And Middle Andaman, Nicobars, Portblair, Mayabunder, Car Nicobar, Garacharma, Pahargaon,Pathergudda, Junglighat.

Kavaratti, Agethi

Daman, Diu, Dadra, Nagar Haveli, Naroli, Dabhel, Silvassa.

Karaikal, Mahe, Pondicherry, Yanam, Kurumbapet, Manavely, Ozhukarai, Thirumalairayanpattinam, Villianur, Puducherry.

Chandigarh