Aluminized Steel Type-2 is steel coated on both sides with commercially pure Aluminium & is called as Aluminized Steel Type 2; ALIOTA-S. Thus, the attractive feature of the Type 2 aluminized steel is that they economically combine the surface characteristics of aluminium accompanied by the strength & rigidity of stainless steel.

Coating Type 2 is intended principally for use in applications requiring corrosion resistance & is available only as a coating on Commercial Steel, Forming Steel, Structural Steel as well as High Strength-Low Alloy Steel.

The process of making aluminized steel Type 2 is done by dipping appropriate steel in hot molted pure Aluminium (99.9%) & thus called hot dip coated Aluminized Steel.

The coating of aluminium comprises of two layers viz.

an aluminium layer &

an underlying hard aluminium-iron (Al-Fe) intermetallic alloy layer.

The total weight of Aluminium coating on Type 2 Aluminized Steel is about twice that on Type 1, or approximately 1.0 oz/ft2, (305.152 g/m2) which is equivalent to 0.002 in. (2 mils) thickness per side.

The Al-Fe layer is formed by the interaction of molten commercial pure aluminium with the steel surface (which has Fe) & this bonds the coating to the base metal firmly. The intermetallic alloy layer also supplements the aluminium layer & acts as a second line of defense to ensure long term durability in corrosive conditions. Control & uniformity in the alloy layer thickness assures the degree of coating necessary for manufacturing various products, for example corrugated steel pipes.

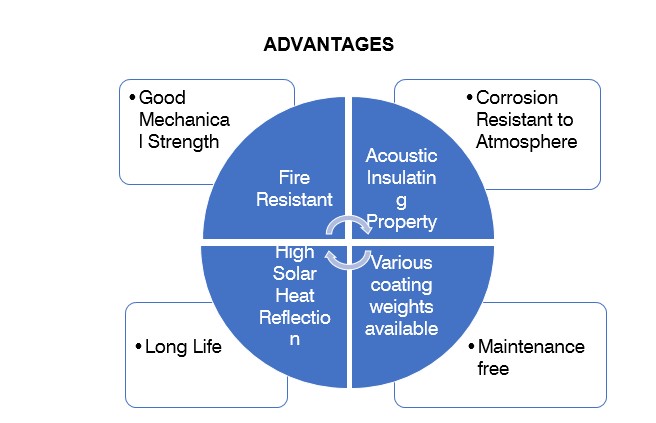

ALUMINIZED Steel Type 2, ALIOTA-S, has excellent atmospheric corrosion resistance as well as fire resistance. For this reason, it is principally intended to be used for these applications. For instance, Aluminized Steel Type 2, ALIOTA-S, is widely used in refineries, chemical as well as petrochemical industries.

Furthermore, ALIOTA-S, due to its excellent atmospheric corrosion resistance, is used as an excellent weatherproofing material. This undoubtedly makes it the best option for insulations in coastal areas, offshore & onshore oil & gas industrial installations for providing metallic jacketing.

Unlike stainless steel, which is highly corrosion-resistant but more expensive, aluminized steel provides a cost-effective alternative with superior heat reflectivity and oxidation resistance, making it ideal for high-temperature applications.

ALIOTA-S offers good hot & cold insulation along with sound insulation.

It is widely used in Europe, the Middle East as well as the USA.

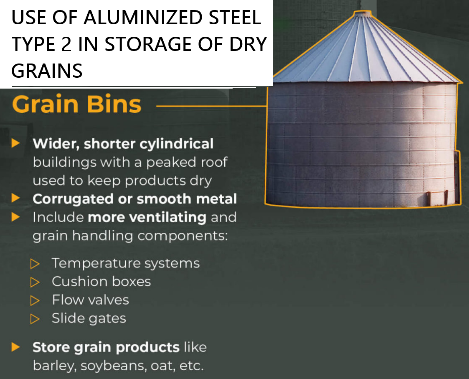

Aluminized Steel Type 2, ALIOTA-S, can be used for roofing & drainage systems, as well as insulation cladding (hot and cold), freshwater drainage, stormwater detention systems, corrugated roofing & siding, drying ovens, air-conditioner condenser housings as well as grain bins for storing dry grains for human & animal consumption.

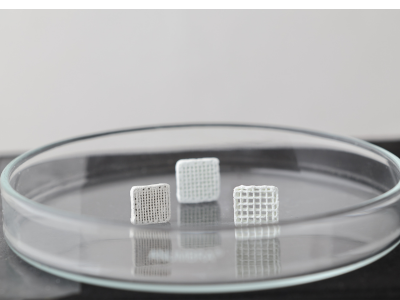

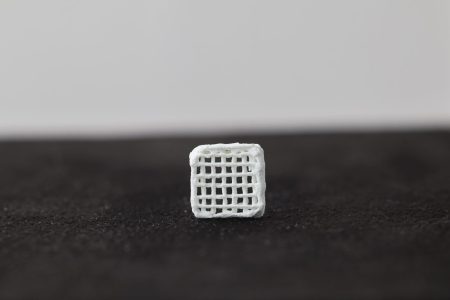

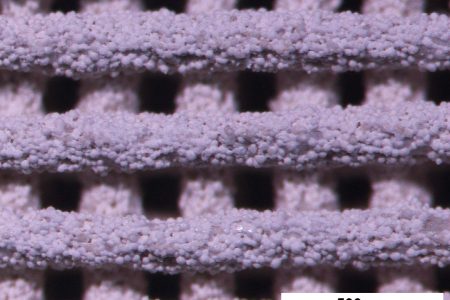

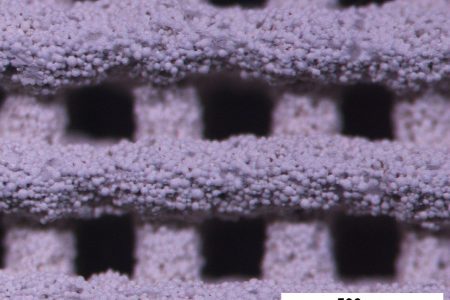

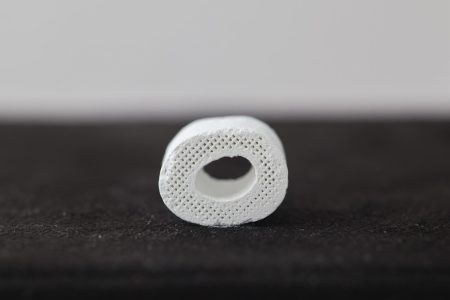

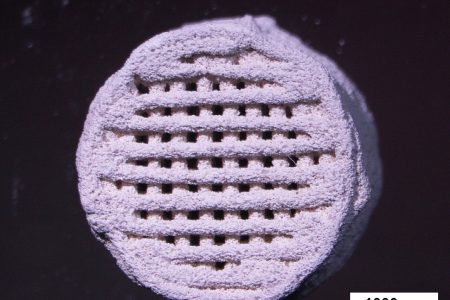

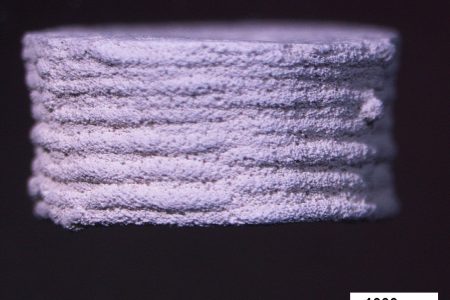

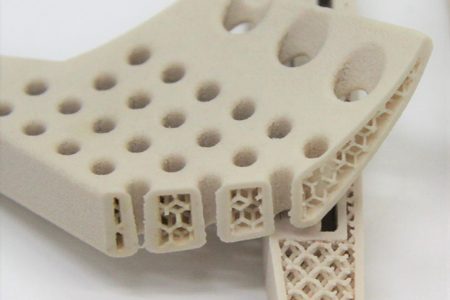

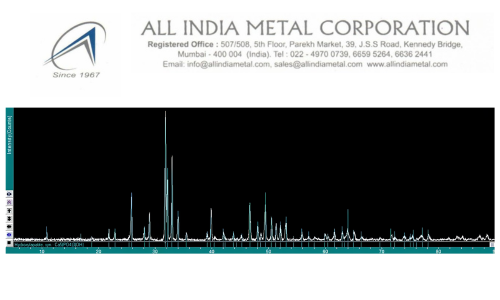

AIMTITE Hydroxyapatite powder is a synthetic micro Hydroxyapatite bio ceramic powder is of spherical shape, with a chemical composition similar to the bone. AIMTITE is most suited for application in Thermal spraying of biomedical metallic implants to form a bioactive coat, 3D printing, bio inks, Plasma Spraying, bone coating, bone repair & filling & synthetic bone substitute.

AIMTITE is biocompatible & has no adverse side effects on the cells using methods as per ISO standards 10993-5-2009 & 10993-12-2012. The usual average particle size used is between 100-150 microns, but can be tailor made as per customer requirements. For 3D printing applications special particle sizes are available.

The 3D printing of neat hydroxyapatite scaffolds is as a matter of fact difficult to obtain. To obtain target-specific scaffolds hydroxyapatite is either processed with sacrificial materials like polymers or other materials like ceramics or bioactive glass. Moreover, binders like polyacrylamide, PVA, sodium polyacrylate, maltodextrin, etc. thus are used. The 3D constructed components have controlled architecture and porosity. The hydroxyapatite “ink” can be cell-free or have cell-encapsulated materials. Various techniques & moreover, for example, β – Tricalcium phosphate, Calcium sulfate, silk-fibroin, graphene, CNTs etc. have been used to fabricate hydroxyapatite scaffolds.

Thermal Spraying Hydroxyapatite, [Ca10(PO4)6(OH)2], is used in biomedical applications including orthopedic device, dental replacements, tissue engineering & bioactive coating. Hydroxyapatite is used regularly for coating either metallic implants of SS316L or Titanium or Ti6Al4V due its excellent biocompatibility & bioactivity.

Hydroxyapatite stimulates strong a bond between metal & bone. Moreover, Hydroxyapatite coating shields the release of metallic ions of the implant into the body. Thermal spraying is an FDA-approved method for coating biomedical implants.

low flame temperature & high flow velocity of hydroxyapatite particles. For example, typical spray parameters for coating hydroxyapatite on implants are as follows & usually will vary according to the type of equipment & the hydroxyapatite used:

Thermal spraying-based techniques produce thick coatings of several tens of micrometers, even though the use of a feedstock as a solution or suspension can result in thinner coatings (5 to 10 μm) when compared with thermal spraying when using dry powders.

Knee implants – Hydroxyapatite coatings have also been used in un – cemented knee prostheses, with coatings applied by plasma spraying to the femoral &/or tibial components. These have more than 20 years of clinical use. For un-cemented hips, the use of un-cemented knee prostheses is generally, for most part, recommended for younger patients (< 60 years).

Plasma-Spray Method is above all used for coating o dental & orthopedic implants. A coating on Titanium or Ti6Al4V can be achieved using this method for the most part. Thinner films of hydroxyapatite ordinarily can be deposited on metal substrates using Suspension Plasma Spray (SPS).

Usually adding Titanium to Hydroxyapatite improves the bonding strength of the coating from about 14.5 to 17.3 MPa. Not to mention that an increase in the adhesion of the coating layer to the implant can be observed if Titanium content increases.

Hydroxyapatite reinforced with 10%w/w of a mix of 80Al2O3 +20TiO2 on Ti6Al4V, moreover, enhances adhesion strength in this case to above 32 MPa.

Sol-Gel Dip Coating Method for applying hydroxyapatite layers involves the formation of Sol-Gel using Calcium Nitrate & Phosphorus pentoxide or triethyl phosphate using aqueous or alcoholic solvents for the most part. Moreover, this is followed by dipping the substrate into the sol-gel over time. It is simply subsequently withdrawn & then dried.

This process is thus simple, fast, cheap & in particular, allows uniform deposition of hydroxyapatite onto complex surfaces at low temperatures.

Electrochemical The electrochemical Deposition Method in particular allows progressive nucleation & growth of hydroxyapatite coat. This leads to a demonstrably homogenous deposition, controlled thickness & reduced decomposition of the hydroxyapatite layer. Besides, Cathodic deposition systems used are either Electrophoretic or Electrolytic.

Likewise, Graphite or Platinum are used as anodes. Hydroxyapatite can additionally be combined with CNTs, ZrO2, TiO2, etc. to achieve better properties. The following table is guidance, comparing electrodeposition methods drawn from various references.

High-Velocity Suspension Plasma Spraying (HVSPS) Method for coating metal substrates, by all means, enhances bioactivity, prevents wearing & corrosion of implants as well as controls the release of harmful metal ions in the body. This method is especially widely used.

The High-Velocity Oxygen-Fuel (HVOF) allows for the formation of a suspension spraying layer. In the same manner, the high velocity of powders allows the formation of a uniform protective coat with low porosity.

Fine or Nano Powders of Hydroxyapatite can be thermally sprayed directly using plasma or gas jets. Aqueous medium &/or Diethylene Glycol suspensions of hydroxyapatite can also be used. Additionally, the coating produced does not delaminate from the substrate significantly.

| Application of Aimtite | Average Particle Sizes (μm) |

| 3D Printing | 15 100 200 |

| Thermal Spraying | 15 50 100 – 150 |

| Bone Coating | 50 |

| Bone Repair | 200 3mm |

| Bone Filling | 3mm |

| Application of Aimtite | Average Particle Sizes (μm) |

| 3D Printing | 15 100 200 |

| Thermal Spraying | 15 50 100 – 150 |

| Bone Coating | 50 |

| Bone Repair | 200 3mm |

| Bone Filling | 3mm |

Ceramic coated pipes are a revolutionary addition to the world of plumbing and fluid transport. Here’s some information about them:

What are Ceramic Coated Pipes? Ceramic coated pipes are metal pipes that have been treated with a ceramic layer. This ceramic layer is created through a process called thermal spraying, where a ceramic material is heated until it becomes molten, then sprayed onto the pipe’s surface where it solidifies and bonds with the metal.

Benefits of Ceramic Coated Pipes

Applications of Ceramic Coated Pipes Ceramic coated pipes are used in a variety of industries, including oil and gas, mining, power generation, and chemical processing. They are particularly useful in situations where pipes are exposed to corrosive substances, high temperatures, or abrasive materials.

In conclusion, ceramic coated pipes offer a durable and efficient solution for many industrial applications. Their superior performance characteristics can lead to cost savings over time due to reduced maintenance and replacement costs. Whether it’s for a small-scale plumbing project or a large industrial operation, ceramic coated pipes are a smart choice for reliable and long-lasting fluid transport.

Protects the pipe externally from extreme corrosive conditions, including seawater.

Provides insulation by not allowing heat/cold to get transferred to the atmosphere etc.

The coating can resist very high temperatures & does not peel off.

Thin coat does not increase weight of the pipes.