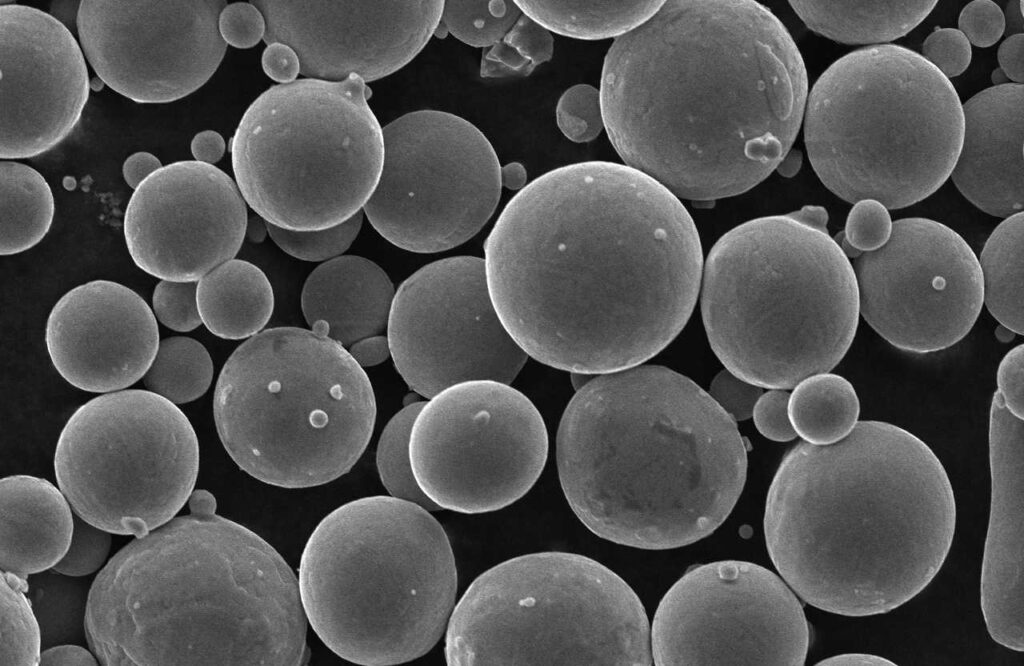

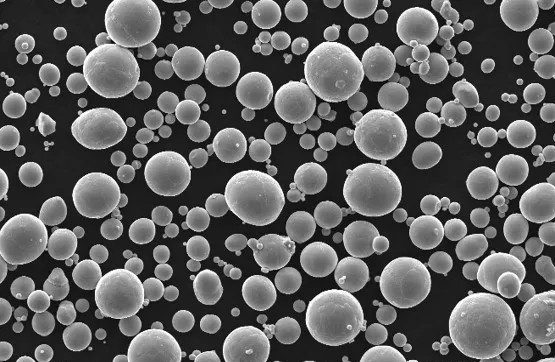

AIMTITE HYDROXYAPATITE POWDER

AIMTITE Hydroxyapatite powder is a synthetic micro Hydroxyapatite powder generally of spherical shape. For the most part, these are most suited for application in 3D printing, Thermal spraying, Plasma Spraying, bone coating, bone repair & bone filling & synthetic bone substitute. Usually, the average particle size is in microns to mm. Hydroxyapatite [Ca10(PO4)6(OH)2] is an example of a bio-ceramic inorganic compound with a chemical composition similar to the bone. Hydroxyapatite undeniably is used as a material for bone substitute & thus finds applications in orthopedic implants & in the same manner in dentistry. Hydroxyapatite is used especially as a bioactive coat on metallic implants & all the more increases the bone & consequently the implant surface.

H Y D R O X Y A P A T I T E (SPHERICAL SHAPED)

A I M T I T E

| Application of Aimtite | Average Particle Sizes (μm) |

| 3D Printing | 15 100 200 |

| Thermal Spraying | 15 50 100 – 150 |

| Bone Coating | 50 |

| Bone Repair | 200 3mm |

| Bone Filling | 3mm |

AIMTITE Hydroxyapatite powder Uses:

3D Printing (Additive Manufacturing)

The 3D printing of neat hydroxyapatite scaffolds is as a matter of fact difficult to obtain. To obtain target-specific scaffolds hydroxyapatite is either processed with sacrificial materials like polymers or other materials like ceramics or bioactive glass. Moreover, binders like polyacrylamide, PVA, sodium polyacrylate, maltodextrin, etc. thus are used. The 3D constructed components have controlled architecture and porosity. The hydroxyapatite “ink” can be cell-free or have cell-encapsulated materials. Various techniques & moreover, for example, β – Tricalcium phosphate, Calcium sulfate, silk-fibroin, graphene, CNTs etc. have been used to fabricate hydroxyapatite scaffolds.

Thermal Spraying

Thermal Spraying Hydroxyapatite, [Ca10(PO4)6(OH)2], is used in biomedical applications including orthopedic device, dental replacements, tissue engineering & bioactive coating. Hydroxyapatite is used regularly for coating either metallic implants of SS316L or Titanium or Ti6Al4V due its excellent biocompatibility & bioactivity.

Hydroxyapatite stimulates strong a bond between metal & bone. Moreover, Hydroxyapatite coating shields the release of metallic ions of the implant into the body. Thermal spraying is an FDA-approved method for coating biomedical implants.

Thermal spraying uses low flame temperature & high flow velocity of hydroxyapatite particles. For example, typical spray parameters for coating hydroxyapatite on implants are as follows & usually will vary according to the type of equipment & the hydroxyapatite used:

Acetylene flow rate: 70 – 75 Lit/minute

Oxygen flow rate: 40 – 45 Lit/minute

Air pressure: 4 – 5 kg/cm2

Powder feed rate: 15 gm/minute

Spray distance: About 10 cm

Thermal spraying based techniques produce thick coatings of several tens of micrometers, even though the use of a feedstock as a solution or suspension can result in thinner coatings (5 to 10 μm) when compared with thermal spraying when using dry powders.

Plasma Spraying of implants

Knee implants – Hydroxyapatite coatings have also been used in un – cemented knee prostheses, with coatings applied by plasma spraying to the femoral &/or tibial components. These have more than 20 years of clinical use. For un-cemented hips, the use of un-cemented knee prostheses is generally, for most part, recommended for younger patients (< 60 years).

Hydroxyapatite coat on above metal substrates is done using four methods:

1. Plasma-Spray Method

2. Sol-Gel Dip Coating Method

3. Electrochemical Deposition Method & lastly

4. High-Velocity Suspension Plasma Spraying (HVSPS) Method

1. Plasma-Spray Method

Plasma-Spray Method is above all used for coating o dental & orthopedic implants. A coating on Titanium or Ti6Al4V can be achieved using this method for the most part. Thinner films of hydroxyapatite ordinarily can be deposited on metal substrates using Suspension Plasma Spray (SPS).

Usually adding Titanium to Hydroxyapatite improves the bonding strength of the coating from about 14.5 to 17.3 MPa. Not to mention that an increase in the adhesion of the coating layer to the implant can be observed if Titanium content increases. Hydroxyapatite reinforced with 10%w/w of a mix of 80Al2O3 +20TiO2 on Ti6Al4V, moreover, enhances adhesion strength in this case to above 32 MPa.

2. Sol-Gel Dip Coating Method–

Sol-Gel Dip Coating Method for applying hydroxyapatite layers involves the formation of Sol-Gel using Calcium Nitrate & Phosphorus pentoxide or triethyl phosphate using aqueous or alcoholic solvents for the most part. Moreover, this is followed by dipping the substrate into the sol-gel over time. It is simply subsequently withdrawn & then dried. This process is thus simple, fast, cheap & in particular, allows uniform deposition of hydroxyapatite onto complex surfaces at low temperatures.

3. Sol-Gel Dip Coating Method–

Electrochemical The electrochemical Deposition Method in particular allows progressive nucleation & growth of hydroxyapatite coat. This leads to a demonstrably homogenous deposition, controlled thickness & reduced decomposition of the hydroxyapatite layer. Besides, Cathodic deposition systems used are either Electrophoretic or Electrolytic. Likewise, Graphite or Platinum are used as anodes. Hydroxyapatite can additionally be combined with CNTs, ZrO2, TiO2, etc. to achieve better properties. The following table is guidance, comparing electrodeposition methods drawn from various references.

| Coating Composition | Film Thickness (μm) | Adhesive Strength (MPa) |

| CoCrMo + HAP | 0.2 | 17.5 |

| Ti6Al4V + HAP (flake-shaped) | 10 | 6.8 |

| Ti6Al4V + HAP (spherical) | 10 | 10.7 |

| Ti6Al4V + HAP/CNT-Ti | 10 | 10.6 |

| Ti6Al4V + HAP (needle-shaped) | 10 | 8.5 |

| Ti + HAP (with & without oxidation) | 3 & 3 | 5.0 & 7.3 |

| Ti + HAP | 10 | 15.3 |

| Ti + SWNTs/HAP | 10 | 25.7 |

| Ti6Al4V + HAP | 30 | 13.8 |

| Ti6Al4V + TiO 2 (10 V)/HAP | 30 | 21.0 |

| Ti6Al4V + TiO 2 (20 V)/HAP | 30 | 13.1 |

| Ti6Al4V + TiO 2 (50 V)/HAP | 30 | 11.9 |

4. High-Velocity Suspension Plasma Spraying

High-Velocity Suspension Plasma Spraying (HVSPS) Method for coating metal substrates, by all means, enhances bioactivity, prevents wearing & corrosion of implants as well as controls the release of harmful metal ions in the body. This method is especially widely used.

The High-Velocity Oxygen-Fuel (HVOF) allows for the formation of a suspension spraying layer. In the same manner, the high velocity of powders allows the formation of a uniform protective coat with low porosity.

Fine or Nano Powders of Hydroxyapatite can be thermally sprayed directly using plasma or gas jets. Aqueous medium &/or Diethylene Glycol suspensions of hydroxyapatite can also be used. Additionally, the coating produced does not delaminate from the substrate significantly.

SEM

You May Also Be Interested In

We are Hydroxyapatite powder Supplier in india, Request a free sample of Hydroxyapatite powder & Nano Hydroxyapatite Powder

We are especially wholesale Hydroxyapatite powder & Nano Hydroxyapatite powder to more than 60 locations worldwide. For example we offer high quality Hydroxyapatite powder. All India Metal Corporation is Hydroxyapatite Powder Manufacturer. A dedicated professional supplier of Hydroxyapatite powder in India including Nano Hydroxyapatite powder in India. All India Metal Corporation in the meanwhile is looking for more Stockholders in Middle East, & Europe, Africa & Far East Asia to sell our Hydroxyapatite Powder & Nano Hydroxyapatite Powder so mail us at engg@allindiametal.com to become our authorized dealer & distributor of Hydroxyapatite powder & Nano Hydroxyapatite Powder in your country.

Special price of Hydroxyapatite Powder & Nano Hydroxyapatite Powder

Special price offer in the meanwhile of Hydroxyapatite powder & Nano Hydroxyapatite Powder in Aurangabad, Haryana Khopoli, Jaipur, & Gurgaon, Maharashtra, Karnataka, & Delhi, Faridabad, Ludhiana, Kolhapur, Gujarat & Punjab, Rajasthan, Indore, Rajkot, & Chhattisgarh, Kolkata, Karnataka, Raipur, Vadodara, Ghaziabad, & Pune, Nagpur, Bangalore, & Pune, Chennai, Ahmedabad, West Bengal, & Madhya Pradesh, Tamil Nadu & Uttar Pradesh. We have an attractive price list of Hydroxyapatite powder in Germany, New Zealand & Taiwan, Myanmar, Senegal & Peru, Kuwait, Bangladesh, & South Korea, Ghana, Australia, & Qatar, Japan, China, UK, Philippines Ethiopia, Thailand, Angola, Nigeria, Zimbabwe, Malaysia, Indonesia, UAE, France & Argentina. Finally, for sample of Hydroxyapatite powder call us or mail to engg@allindiametal.com for Hydroxyapatite powder Price & Nano Hydroxyapatite Powder Price

Check the current price of Hydroxyapatite powder & Nano Hydroxyapatite powder before you buy from other Hydroxyapatite powder Suppliers. To clarify send an inquiry for Hydroxyapatite powder & Nano Hydroxyapatite powder to check types & sizes. You can mail ordinarily to engg@allindiametal.com for hydroxyapatite powder Manufacturers.

Call Now For Hydroxyapatite Powder & Nano Hydroxyapatite Powder free sample